Cigaban Injin Casting

Ƙa'idar aiki na nau'in nau'in nau'in na'ura mai ci gaba da yin simintin gyare-gyare yana dogara ne akan irin ra'ayoyi iri ɗaya kamar na'urorin jefar matsi na mu. Maimakon cika kayan ruwa a cikin flask za ku iya samar da / zana takarda, waya, sanda, ko bututu ta amfani da ƙirar graphite. Duk wannan yana faruwa ba tare da wani kumfa na iska ko raguwar porosity ba. The injin da kuma high injin ci gaba da simintin gyaran kafa ana amfani da m don yin high-karshen ingancin wayoyi kamar bonding waya, semiconductor, Aerospace filin.

-

Hasung-High Vacuum Kayan Cigaban Simintin Kayan Aiki Don Ƙarfe Masu daraja

Karfe masu aiki:kayan karafa kamar zinari, K zinariya, azurfa, tagulla, da kayan kwalliyar su

Masana'antun aikace-aikace:kayan haɗin waya, simintin kayan ado, sarrafa ƙarfe mai daraja, dakunan gwaje-gwaje na jami'a da sauran fannoni masu alaƙa

Amfanin samfur:

1. Babban injin (6.67 × 10-3pa), babban narkewa mai narkewa, babban samfuri mai yawa, ƙarancin iskar oxygen, babu pores, dacewa don samar da wayar haɗin kai mai inganci;

2. Anti oxidation, inert gas kariya tacewa, don magance matsalar gami hadawan abu da iskar shaka;

3. Launi na Uniform, electromagnetic da hanyoyin motsa jiki na jiki suna sa launin gami ya zama iri ɗaya;

4. Samfurin da aka gama yana da ƙasa mai santsi kuma yana ɗaukar ƙirar ƙira ta ƙasa. Ƙaƙwalwar motsi ta yi amfani da magani na musamman, kuma samfurin da aka gama ba shi da lahani ga farfajiya da kuma santsi;

5. Daidaitaccen kula da zafin jiki ± 1 ℃, ta yin amfani da mita masu kula da zafin jiki da aka shigo da su da kuma tsarin kula da zafin jiki na PID mai hankali, tare da bambancin zafin jiki na ± 1 ℃;

6. 7-inch allon taɓawa mai cikakken launi, mafi dacewa don dubawa / taɓawa, sabon tsarin, sauƙin UI mai sauƙi, mai sauƙin aiki tare da taɓawa ɗaya kawai;

7. Kariya da yawa, kariyar tsaro da yawa, amfani da damuwa kyauta

-

Kyawawan Ƙarfe Mai Tsare Tsare-tsare Injin Ci gaba da Yin Simintin Samfura

A kwance injin ci gaba da yin simintin fa'ida

1. Inganta ingancin samfur

2. Ingantaccen sarrafa tsari

3. Haɓaka Haɓaka

4. Amfanin makamashi

Halayen na'ura mai ci gaba da yin siminti a kwance

1. Tsare Tsare Tsare

2. Vacuum Chamber

3. Tsarin sanyaya

4. Automation da tsarin sarrafawa

5. Babban ƙarfin narkewa

6. Kyakkyawan samfurin simintin gyare-gyare

-

Ci gaba da simintin gyare-gyaren na'ura na Zinariya Azurfa Copper Alloy 20kg 30kg 50kg 100kg

1.Da zaran azurfa zinariya tsiri waya tube sandana'ura mai ci gabadon kayan ado da aka kaddamar a kasuwa, ya samu tabbatacce feedback daga abokan ciniki da yawa, wanda ya ce irin wannan samfurin iya yadda ya kamata warware su bukatun.Bugu da ƙari, da samfurin da aka yadu amfani da Karfe Casting.

2.Continuous Casting Machine for Yin Rod Strip Pipe tare da 20kg 30kg 50kg 100kg idan aka kwatanta da irin wannan samfurori a kasuwa, yana da fa'idodi masu ban sha'awa a cikin yanayin aiki, inganci, bayyanar, da dai sauransu, kuma yana jin daɗin suna a kasuwa.Hasung yana taƙaita lahani na samfuran da suka gabata, kuma yana ci gaba da inganta su. Ƙayyadaddun na'ura mai ci gaba da yin simintin gyare-gyare don yin bututun igiya tare da 20kg 30kg 50kg 100kg za a iya keɓance shi gwargwadon bukatun ku.

-

Babban injin ci gaba da simintin simintin gyare-gyare don Sabbin Kayayyakin Simintin gyare-gyaren Waya ta Zinare Azurfa

Yin simintin simintin gyare-gyare na lantarki irin su haɗin gwal na azurfa tagulla da waya ta musamman mai tsabta Tsararren tsarin wannan kayan aiki ya dogara ne akan ainihin bukatun aikin da tsari, kuma yana yin cikakken amfani da fasaha na zamani.

1. Karɓar fasahar dumama mai saurin mita na Jamus, bin diddigin mitar atomatik da fasahar kariya da yawa, waɗanda zasu iya narkewa cikin ɗan gajeren lokaci, adana kuzari da aiki yadda yakamata.

2. Rufaffiyar nau'in + inert gas kariya narke ɗakin na iya hana iskar shaka na zukar albarkatun kasa da kuma hadawa na impurities. Wannan kayan aikin ya dace da simintin gyare-gyare na kayan ƙarfe masu tsabta ko kuma a sauƙaƙe oxidized ƙananan ƙarfe.

3. Yi amfani da rufaffiyar + iskar gas don kare ɗakin narkewa. Lokacin narkewa a cikin yanayin iskar iskar gas, asarar iskar shaka ta carbon mold kusan ba ta da kyau.

4. Tare da aikin motsa jiki na lantarki + motsa jiki na injiniya a ƙarƙashin kariya na inert gas, babu rabuwa a launi.

5. Yin amfani da Tsarin Kuskure (anti-wawa) tsarin sarrafawa ta atomatik, aikin ya fi dacewa.

6. Yin amfani da tsarin kula da zafin jiki na PID, yawan zafin jiki ya fi daidai (± 1 ° C).

7. HVCC jerin high injin ci gaba da simintin kayan aiki ne da kansa ɓullo da kuma kerarre, tare da ci-gaba fasaha, amfani da ci gaba da simintin gyare-gyare na high tsarki zinariya, azurfa, jan karfe da sauran gami.

8. Wannan kayan aiki yana amfani da tsarin kula da shirin Mitsubishi PLC, SMC pneumatic da Panasonic servo motor drive da sauran nau'in alamar gida da na waje.

9. narkewa a cikin rufaffiyar + inert gas kariya narkewa dakin, biyu ciyar, electromagnetic stirring, inji stirring, refrigeration, sabõda haka, samfurin yana da halaye na wani hadawan abu da iskar shaka, low asara, babu porosity, babu segregation a launi, da kyau bayyanar.

10. Nau'in Vacuum: High vacuum.

-

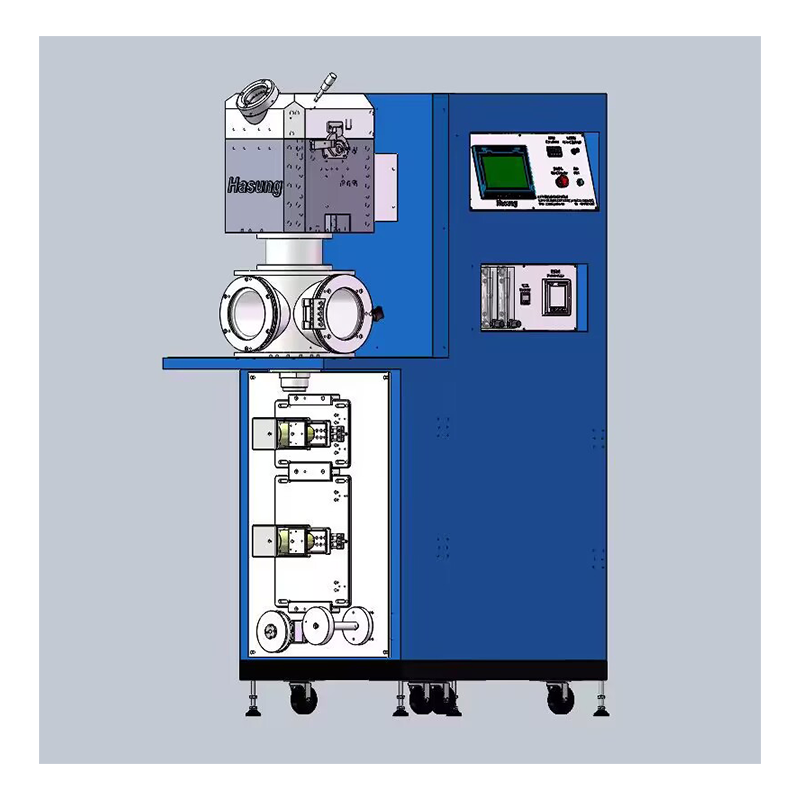

Vacuum Ci gaba da Casting Machine don Garin Zinariya na Copper

Tsarin simintin gyare-gyare na musamman

Don mafi girman ingancin kayan da aka kammala:

Don rage haɗarin iskar shaka yayin narkewa da lokacin zane, muna mai da hankali kan guje wa hulɗar iskar oxygen da kuma saurin rage yawan zafin jiki na kayan ƙarfe da aka zana.

Siffofin don guje wa hulɗar oxygen:

1. Inert gas tsarin ga dakin narkewa

2. Tsarin injin don ɗakin narkewa - na musamman don Hasung injin ci gaba da simintin simintin gyare-gyare (jerin VCC)

3. Rashin iskar iskar gas a mutu

4. Ma'aunin zafin jiki na gani mutu

5. Ƙarin tsarin sanyaya na biyu

6. Duk waɗannan matakan suna da kyau musamman ga allunan da ke ɗauke da tagulla kamar jajayen zinare ko na azurfa kamar yadda waɗannan kayan sukan haifar da oxidise cikin sauƙi.Za a iya lura da tsarin zane da halin da ake ciki ta hanyar lura da windows.

Matsakaicin digiri na iya zama bisa ga buƙatar abokan ciniki.

-

Cigaban Injin Simintin Ɗaukaka don Alloy na Azurfa na Zinariya

Zane na wannan tsarin kayan aiki ya dogara ne akan ainihin bukatun aikin da tsari, ta hanyar amfani da fasahar zamani na zamani.

1. Yin amfani da fasahar dumama na Jamusanci, saurin mita ta atomatik da fasahar kariya da yawa, ana iya narke shi cikin ɗan gajeren lokaci, ceton makamashi da kare muhalli, da ingantaccen aiki.

2. Rufaffiyar nau'in + inert gas kariya narke ɗakin na iya hana iskar shaka na zukar albarkatun kasa da kuma hana hadawa na impurities. Wannan kayan aikin ya dace da simintin gyare-gyare na kayan ƙarfe masu tsabta ko kuma a sauƙaƙe oxidized ƙananan ƙarfe.

3. Yin amfani da rufaffiyar + inert gas kariya na narkewa dakin, narkewa da vacuuming ana yi a lokaci guda, da lokaci yana da rabi, da kuma samar da ingancin ya inganta sosai.

4. Narkewa a cikin yanayi maras amfani da iskar gas, asarar iskar shaka ta carbon crucible kusan ba ta da kyau.

5. Tare da aikin motsa jiki na lantarki a ƙarƙashin kariya na iskar gas, babu rabuwa a launi.

6. Yana ɗaukar Tsarin Tabbatar da Kuskure (anti-wawa) tsarin sarrafa atomatik, wanda ya fi sauƙin amfani.

7. Yin amfani da tsarin kula da zafin jiki na PID, yawan zafin jiki ya fi daidai (± 1 ° C). HS-CC jerin ci gaba da simintin kayan aiki an ƙera shi da kansa kuma an kera shi tare da fasahar ci gaba kuma an sadaukar da shi ga narkewa da jefar gwal, azurfa, jan ƙarfe da sauran alluran gami, sanduna, zanen gado, bututu, da sauransu.

8. Wannan kayan aiki yana amfani da tsarin kula da shirin na Mitsubishi PLC, SMC pneumatic da Panasonic servo motor drive da sauran sanannun alamun alama a gida da waje.

9. Narkewa, motsa jiki na lantarki, da firiji a cikin rufaffiyar + inert gas kariya narke dakin, don haka samfurin yana da halaye na babu iskar shaka, low asara, babu pores, babu rabuwa a cikin launi, da kyau bayyanar.

Menene ci gaba da simintin gyare-gyare, menene don haka, menene fa'idodin?

Ci gaba da aikin simintin gyare-gyare hanya ce mai inganci don kera samfuran da aka kammala kamar sanduna, bayanan martaba, slabs, tubes da tubes waɗanda aka yi daga zinariya, azurfa da ƙarfe mara ƙarfe kamar jan karfe, aluminum da gami.

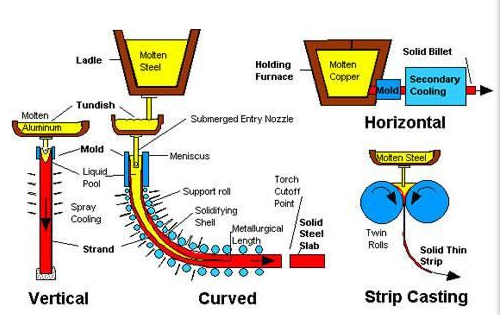

Ko da akwai dabaru daban-daban na ci gaba da yin simintin gyare-gyare, babu wani gagarumin bambanci wajen yin zinare, azurfa, jan karfe ko gami. Bambanci mai mahimmanci shine yanayin simintin simintin gyare-gyare wanda ke tashi daga kusan 1000 ° C a yanayin azurfa ko tagulla zuwa 1100 ° C a cikin yanayin zinari ko sauran gami. Ana ci gaba da jefar da narkakken ƙarfe a cikin jirgin ruwa mai suna ladle kuma yana gudana daga can zuwa simintin simintin a tsaye ko a kwance tare da buɗe baki. Yayin da yake gudana ta cikin mold, wanda aka sanyaya tare da crystallizer, yawan ruwa yana ɗaukar bayanin martaba na mold, ya fara ƙarfafawa a samansa kuma ya bar ƙirar a cikin wani yanki mai ƙarfi. A lokaci guda, ana ba da sabon narke akai-akai zuwa ga ƙirƙira a daidai wannan ƙimar don ci gaba da daidaita madaidaicin da ke barin ƙirar. Ana ƙara sanyaya madauri ta hanyar tsarin feshin ruwa. Ta hanyar yin amfani da ƙarfafa sanyaya yana yiwuwa a ƙara saurin crystallization da kuma samar da a cikin madaidaicin tsari mai kyau, wanda ya ba da samfurin da aka kammala da kyau kayan fasaha. Sa'an nan kuma a daidaita madaidaicin madaidaicin a yanke shi zuwa tsayin da ake so ta hanyar shears ko yankan-tocilan.

Za'a iya ƙara yin aiki akan sassan a cikin ayyukan mirgina cikin layi na gaba don samun sanduna, sanduna, filayen extrusion (blanks), slabs ko wasu samfuran da aka gama da su ta fuskoki daban-daban.

Tarihin ci gaba da yin simintin gyare-gyare

Ƙoƙarin farko na jefa karafa a ci gaba da aiki an yi su ne a tsakiyar ƙarni na 19. A cikin shekara ta 1857, Sir Henry Bessemer (1813-1898) ya sami takardar izinin yin simintin ƙarfe tsakanin rollers biyu masu jujjuyawa don kera shingen ƙarfe. Amma wannan lokacin wannan hanya ta kasance ba tare da kulawa ba. An sami ingantaccen ci gaba daga 1930 zuwa gaba tare da fasahar Junghans-Rossi don ci gaba da yin simintin ƙarfe na haske da nauyi. Dangane da karfe, an ci gaba da yin aikin simintin gyare-gyare a shekara ta 1950, kafin (da kuma bayan) an zuba karfen a cikin tsayayyen tsari don samar da 'ingots'.

Ci gaba da yin simintin gyare-gyare na sandar da ba na ƙarfe ba an ƙirƙira shi ta hanyar tsarin Properzi, wanda Ilario Properzi (1897-1976) ya haɓaka, wanda ya kafa kamfanin Continuus-Properzi.

Amfanin ci gaba da simintin gyaran kafa

Ci gaba da yin simintin gyare-gyare ita ce hanya mafi kyau don kera samfuran da aka kammala masu tsayi masu tsayi kuma suna ba da damar samar da adadi mai yawa a cikin ɗan gajeren lokaci. Microstructure na samfurori yana da ma. Idan aka kwatanta da simintin gyare-gyare, ci gaba da yin simintin gyare-gyare ya fi tattalin arziƙi game da yawan kuzari kuma yana rage raguwa. Bugu da ƙari, ana iya canza kaddarorin samfuran cikin sauƙi ta canza sigogin simintin. Kamar yadda duk ayyukan za a iya sarrafa su da sarrafa su, ci gaba da yin simintin gyare-gyare yana ba da damammaki masu yawa don daidaita samarwa cikin sassauƙa da sauri zuwa canza buƙatun kasuwa da haɗa shi da fasahar digitization (Industrie 4.0).