Granulating Systems

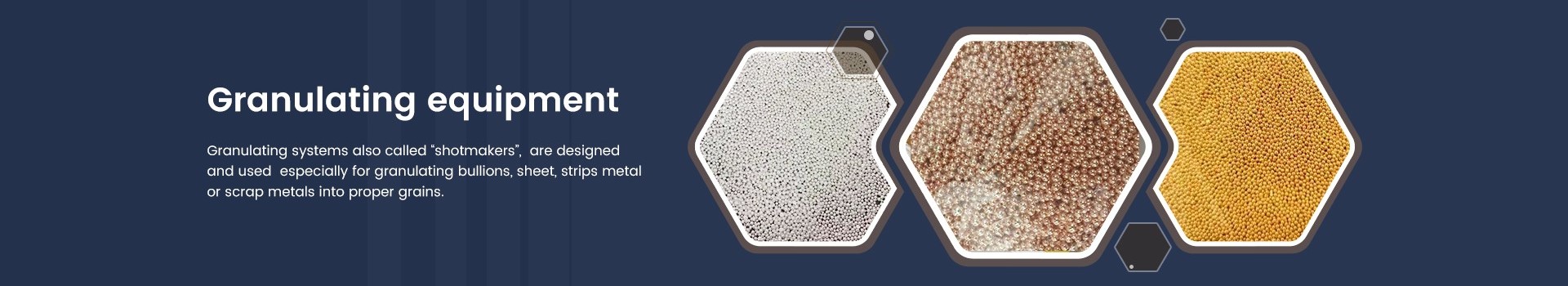

Tsarin granulating wanda kuma ake kira “masu harbi”, an tsara su kuma ana amfani dasu musamman don ƙwanƙwasa bullions, sheet, tube karfe ko tarkace karafa zuwa cikin hatsin da suka dace. Tankuna na granulating suna da sauƙin cirewa don sharewa. Cire hannun don sauƙin cire abin da aka saka tanki. Kayan zaɓin na'urar simintin matsa lamba ko injin ci gaba da simintin simintin gyare-gyare tare da tankin granulating shine mafita don granulating lokaci-lokaci shima. Ana samun tankuna na granulating don duk injuna a cikin jerin VPC. Tsarin nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i) yana da tanki tare da ƙafafu hudu wanda ke motsawa cikin sauƙi da waje.

-

Metal Granulator Machine na Zinariya Azurfa Copper 4kg 6kg 8kg10kg15kg

1. Tare da kula da zafin jiki, daidaito har zuwa ± 1 ° C.

2. Ƙararren ɗan adam, aikin yana da sauƙi fiye da sauran.

3. Yi amfani da mai sarrafa Mitsubishi da aka shigo da shi.

4. Azurfa Granulator tare da sarrafa tempterature (Gold Azurfa Grains Casting Machine, Azurfa Granulating Machine).

5. Wannan inji rungumi dabi'ar IGBT ci-gaba dumama fasahar, da simintin gyaran kafa yana da kyau sosai, da tsarin ne barga da kuma hadari, narkakkar zinariya iya aiki ne na tilas, kuma granulated karfe ƙayyadaddun zabi ne.

6. Gudun granulation yana da sauri kuma babu hayaniya. Cikakkun gwaje-gwaje na ci gaba da ayyukan kariya suna sa injin gabaɗaya amintattu da dorewa.

7. Na'ura yana da tsaga zane kuma jiki yana da ƙarin sarari kyauta.

-

Platinum Granulating Machine Granulating Machine 10kg

Hasung Platinum Shot Maker Granulating Machine idan aka kwatanta da irin waɗannan samfuran a kasuwa, yana da fa'idodi mara misaltuwa dangane da aiki, inganci, bayyanar, da dai sauransu, kuma yana jin daɗin suna a kasuwa.Hasung yana taƙaita lahani na samfuran da suka gabata, kuma yana ci gaba. inganta su. Ƙayyadaddun ƙayyadaddun na'urar Hasung Platinum Shot Maker Granulating Machine za a iya keɓance shi gwargwadon bukatun ku.

Babban fa'idodin sabbin tsararraki na masu harbi

Easy shigarwa na granulating tank tare da dandamali

High quality granulating yi

Ergonomically da daidaitaccen ƙira don aminci da sauƙin sarrafawa

Ingantattun halayen yawo na ruwan sanyaya

Amintaccen rabuwa da ruwa da granules -

Vacuum Shot Maker na Zinariya Azurfa Copper 4kg 8kg 10kg

Zane na wannan tsarin injin granulator ya dogara ne akan ainihin buƙatun tsarin ƙarfe mai daraja ta amfani da fasahar dumama na zamani.

Ana amfani da injin granulator don kera ingantattun hatsi masu kama da nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau‘in innabi) ana amfani da su kera irin su zinare, azurfa, tagulla, da gami, farawa daga albarkatun kasa da Hasung induction dumama ya narka a cikin wani yanayi mai kariya na iskar gas, sannan a jefa shi cikin tankin ruwa yana wucewa. ta hanyar ƙugiya mai faɗowa da yawa wanda ke aiki azaman mai fasa kwarara.

Injin granulator yana ɗaukar cikakken injin injin da iskar gas mai narkewa da granulating, injin na iya motsawa ta atomatik a cikin narkewa, motsawar wutar lantarki, da firiji a cikin rufaffiyar + vacuum/iner gas kariya narkewa dakin, ta yadda samfurin yana da halaye na babu hadawan abu da iskar shaka, super. ƙananan hasara, babu pores, babu rarrabuwa a cikin launi, da kyakkyawan bayyanar tare da girman uniform.

Wannan kayan aiki yana amfani da tsarin kula da shirin Mitsubishi PLC, SMC pneumatic da Panasonic servo motor drive da sauran sanannun abubuwan haɗin alama a gida da waje.

-

High Vacuum Granulating System for Gold Azurfa Copper 20kg 50kg 100kg

High injin granulator granulates daraja karfe barbashi ga simintin bonding waya: zinariya, azurfa da jan karfe, bonding waya ne yafi amfani ga semiconductor kayan, photovoltaic waldi kayan, likita kayan aiki, wucin gadi m machines.Also wadannan high injin karfe shotmakers an ɓullo da musamman ga granulating bullions. , karfen takarda, ko tarkace cikin hatsi masu dacewa. Tankuna na granulating suna da sauƙin cirewa don tsaftacewa. HS-VGR High Vacuum Granulating Machines suna samuwa tare da iya aiki daga 20kg har zuwa 100kg. Kayan jiki suna amfani da bakin karfe 304 wanda ke tabbatar da ingancin tsawon rayuwa ta amfani da shi, kuma tare da ƙirar ƙira don cika ingancin da ake buƙata.

Manyan aikace-aikace:

1. Shirye-shiryen kayan kwalliya daga zinare da gwanayen gwal

2. Shirye-shiryen kayan haɗin gwal

3. Shirye-shiryen allo daga abubuwan da aka gyara

4. Tsabtace karfe da aka riga aka jefa

5. Yin hatsin ƙarfe don cinikin ƙarfe mai darajaAn ƙirƙiri jerin VGR don samar da granules na ƙarfe tare da girman hatsi tsakanin 1.5 mm da 4mm. Tsarin sun dogara ne akan raka'o'in granulation na Hasung, amma duk mahimman abubuwan haɗin gwiwa, musamman tsarin jet, ci gaba ne na musamman.

Babban ƙarfin kamar 100kg injin granulating tsarin zaɓi ne don a sanye shi da tsarin kula da Panel Touch na Mitsubishi PLC.

Kayan aiki na zaɓi na matsa lamba ko injin ci gaba da simintin gyare-gyare tare da tankin granulating shine mafita mai dacewa don granulating lokaci-lokaci. Ana samun tankuna na granulating don duk injuna a cikin jerin VC.

Babban fa'idodin sabbin tsararraki na masu harbi:

1. Easy shigarwa na granulating tank

2. Saurin-canzawa tsakanin tsarin simintin gyare-gyare da granulating

3. Ergonomically da daidaitattun ƙira don aminci da sauƙin kulawa

4. Ingantattun halayen yawo na ruwan sanyi

5. Amintaccen rabuwa da ruwa da granules

6. Mafi ƙarfi da inganci don ƙungiyoyi masu tace karafa masu daraja.

7. Ajiye makamashi, saurin narkewa. -

Metal Granulating Machine for Gold Azurfa Copper Alloy 20kg 30kg 50kg 100kg 150kg

1. Tare da kula da zafin jiki, daidaito har zuwa ± 1 ° C.

2. Ƙararren ɗan adam, aikin yana da sauƙi fiye da sauran.

3. Yi amfani da mai sarrafa Mitsubishi da aka shigo da shi.

4. Azurfa Granulator tare da sarrafa tempterature (Gold Azurfa Grains Casting Machine, Azurfa Granulating Machine).

5. Wannan inji rungumi dabi'ar IGBT ci-gaba dumama fasahar, da simintin gyaran kafa yana da kyau sosai, da tsarin ne barga da kuma hadari, narkakkar zinariya iya aiki ne na tilas, kuma granulated karfe ƙayyadaddun zabi ne.

6. Gudun granulation yana da sauri kuma babu hayaniya. Cikakkun gwaje-gwaje na ci gaba da ayyukan kariya suna sa injin gabaɗaya amintattu da dorewa.

7. Na'ura yana da tsaga zane kuma jiki yana da ƙarin sarari kyauta.

-

Karamin Girman Ƙarfe Granulator Kayan Aikin Granulating don Azurfa na Zinariya

Ƙananan masu harbin karfe. Tare da sarrafa zafin jiki, daidaito har zuwa ± 1 ° C.

Ƙararren ɗan adam, aikin ya fi sauƙi fiye da sauran.

Yi amfani da mai sarrafa Mitsubishi da aka shigo da shi.Wannan injin yana ɗaukar fasahar dumama IGBT ta Jamus, tasirin simintin yana da kyau sosai, tsarin yana da karko kuma mai aminci, ƙyallen gwal na zaɓi ne, kuma ƙayyadaddun ƙarfe granulated zaɓi ne. Gudun granulation yana da sauri kuma babu hayaniya. Cikakkun gwaje-gwaje na ci gaba da ayyukan kariya suna sa injin gabaɗaya amintattu da dorewa. Injin yana da tsaga ƙira kuma jiki yana da ƙarin sarari kyauta.

Yin amfani da ba tare da kwampresar iska ba, yin simintin gyare-gyare ta hanyar injin buɗewa da hannu.

Wannan GS Series granulating tsarin ya dace da ƙananan iya aiki daga 1kg zuwa 8kg iya aiki (zinariya), yana da kyau ga abokan ciniki waɗanda ke da ƙananan sarari.

Mene ne karfe granulation?

Granulation (daga Latin: granum = “hatsi”) fasaha ce ta maƙerin zinari inda ake ƙawata saman jauhari da ƙananan sassa na ƙarfe mai daraja, mai suna granules, bisa ga tsarin ƙira. An samo mafi daɗaɗɗen binciken archaeological na kayan ado da aka yi da wannan fasaha a cikin kaburburan sarauta na Ur, a Mesopotamiya kuma ya koma 2500 BC Daga wannan yanki, dabarar ta yadu zuwa Anatolia, a Siriya, zuwa Troy (2100 BC) kuma daga ƙarshe zuwa Etruria. (karni na 8 BC). A hankali bacewar al'adun Etruscan tsakanin ƙarni na uku da na biyu BC ne ya haifar da raguwar granulation.1 Tsohuwar Helenawa ma sun yi aikin granulation, amma masu sana'a na Etruria ne suka shahara da wannan fasaha saboda su m tura na lafiya foda granulation2 ba tare da fili amfani da wuya solder.

Granulation tabbas shine mafi ban mamaki da ban sha'awa na tsoffin dabarun ado. Masu sana'a Fenici da Greci ne suka gabatar da su zuwa Etruria a karni na 8 BC, inda ilimin karafa da kuma amfani da karafa masu daraja ya riga ya shiga wani mataki na ci gaba, kwararrun maƙeran zinariya na Etruscan sun yi wannan dabarar nasu don ƙirƙirar ayyukan fasaha na sarƙaƙƙiya da kyan gani.

A cikin rabin farkon shekarun 1800 an gudanar da tona abubuwa da yawa a kusa da Roma (Cerveteri, Toscanella da Vulci) da Kudancin Rasha (Kertch da Taman peninsulas) wanda ya bayyana tsoffin kayan ado na Etruscan da Girkanci. An ƙawata waɗannan kayan ado da granulation. Kayan adon ya zo da hankalin dangin Castellani na kayan ado waɗanda ke da hannu sosai a cikin binciken kayan ado na zamanin da. Abubuwan da aka samo daga wuraren binne Etruscan sun fi jan hankali saboda amfani da granules masu kyau. Alessandro Castellani ya yi nazarin waɗannan kayan tarihi dalla-dalla don ƙoƙarin buɗe hanyar ƙirƙira su. Sai a farkon karni na 20, bayan mutuwar Castellani, a ƙarshe aka warware wuyar warwarewar colloidal/eutectic soldering.

Ko da yake asirin ya kasance asirce ga Castellanis da mutanen zamaninsu, sabon kayan ado na Etruscan da aka gano ya haifar da farfaɗowar kayan ado na archaeological kusan shekarun 1850. An gano fasahohin maƙeran zinari waɗanda suka baiwa Castellani da sauransu damar sake yin wasu daga cikin tsoffin kayan adon da aka taɓa hakowa cikin aminci. Yawancin waɗannan fasahohin sun bambanta da waɗanda Etruscans suka yi amfani da su duk da haka suna ba da sakamako mai yuwuwa. Yawancin waɗannan abubuwan kayan ado na Farfaɗo na Archaeological yanzu suna cikin tarin kayan ado masu mahimmanci a duniya, tare da takwarorinsu na da.

GRANULES

Ana yin granules ne daga ƙarfe ɗaya da ƙarfe wanda za a shafa su. Hanya ɗaya tana farawa ta hanyar jujjuya takarda mai sirara ta ƙarfe da almakashi kunkuntar gefuna a gefen. An gyara gefuna kuma sakamakon shine yawancin ƙananan murabba'ai ko platelets na ƙarfe. Wata dabarar ƙirƙira hatsi tana amfani da wayoyi ƴaƴan sirara da aka naɗe a kusa da sirararen mandrel, kamar allura. Sannan ana yanka nada cikin kananan zoben tsalle. Wannan yana haifar da zobba masu ma'ana sosai waɗanda ke haifar da mafi girman girman granules. Manufar ita ce ƙirƙirar sassa da yawa girman girman da ke da diamita wanda bai fi 1 mm girma ba.

Ana lulluɓe da farantin karfe ko zoben tsalle a cikin foda na gawayi don hana su mannewa yayin harbe-harbe. An lulluɓe ƙasan ƙugiya da garwashin gawayi kuma ana yayyafa guntun ƙarfe a kai ta yadda za su yi daidai gwargwado. Ana biye da shi da wani sabon foda na garwashi da ƙarin sassa na ƙarfe har sai kullun ya cika kusan kashi uku. Ana harba tukunyar a cikin kasko ko tanda, kuma sassa masu daraja na ƙarfe suna jujjuyawa zuwa ƙananan sassa a yanayin zafi na narkewar gawa. Waɗannan sabbin sassan da aka ƙirƙira an bar su su yi sanyi. Daga baya sai a tsaftace su cikin ruwa ko, idan za a yi amfani da dabarar saida, a tsinke cikin acid.

Granules na masu girma dabam ba zai haifar da ƙira mai daɗi ba. Tun da yake ba shi yiwuwa maƙerin zinare ya ƙirƙiro daidaitattun filaye masu daidaitattun diamita guda ɗaya, dole ne a jera granules ɗin kafin amfani. Ana amfani da jerin sieves don warware granules.

Yaya ake yin harbin zinare?

Shin tsarin yin harbin zinare ne kawai zubar da narkakkar zinare a hankali a cikin ruwa bayan kun dumama shi? Ko kuna yin duka a lokaci ɗaya? Menene manufar yin harbin zinare maimakon ingots ect.

Ba a ƙirƙira harbin zinare ta hanyar zubo daga leɓan akwati. Dole ne a fitar da shi ta hanyar bututun ƙarfe. Kuna iya yin mai sauƙi ta hanyar tono ƙaramin rami (1/8") a cikin kasan kwanon narke, wanda za'a sanya shi a kan kwandon ruwa, tare da fitilar a kan tasa, a kusa da ramin. zinare daga daskarewa a cikin tasa lokacin da aka canza shi daga tasa mai narkewa wanda aka narkar da foda na zinari saboda dalilan da suka kasance da wuya a fahimta, wanda ke yin harbi, maimakon cornflakes.

Shot ya fi son masu amfani da zinariya, domin yana sa auna adadin da ake so cikin sauƙi. Maƙeran zinare masu hikima ba sa narke zinariya da yawa a lokaci ɗaya, in ba haka ba yana iya haifar da lalacewa (haɗin gas).

Ta hanyar narkewa kawai adadin da ake buƙata, ƙananan adadin da ya rage (sprue) za a iya narkar da shi tare da tsari na gaba, yana tabbatar da cewa zinariyar da aka sake narkar da baya taruwa.

Matsalar narkewar zinare akai-akai ita ce karfen tushe (yawanci jan ƙarfe, amma ba'a iyakance shi ga jan ƙarfe ba) oxidizes kuma ya fara ƙirƙirar iskar gas wanda ke taruwa cikin ƙananan aljihu a cikin simintin gyare-gyare. Yawancin duk mai yin kayan ado da ke yin simintin gyare-gyare sun sami wannan ƙwarewar, kuma galibi suna yin lissafin dalilin da ya sa ba za su yi ba, ko kuma ba sa son yin amfani da zinare da aka yi amfani da su a baya.