Hasung T2 Kayan Adon Wuta na Matsayin Simintin Simintin Gyaran Mashin

Me yasa kuke Zaɓan Injin Hasung Vacuum Pressure Casting Machine?

Hasung T2 Vacuum Casting Machines kwatanta da sauran kamfanoni

1. Daidaitaccen aikin simintin gyare-gyare

2. Kyakkyawan saurin narkewa. Gudun narkewa yana cikin mintuna 2-3.

3. Matsi mai ƙarfi.

4. Abubuwan asali na Hasung sune sanannun samfuran gida, Japan da Germanu.

5. Daidaitaccen aikin simintin gyare-gyare

6. Taimakawa tunanin shirin 100

7. tanadin makamashi. Tare da ƙarancin wutar lantarki 10KW 380V 3 lokaci.

8. Yin amfani da nitrogen ko argon kawai, babu buƙatar haɗi zuwa iska mai kwakwalwa.

Ma'aunin Fasaha

| Model No. | HS-T2 |

| Wutar lantarki | 380V, 50/60Hz, 3 matakai |

| Tushen wutan lantarki | 10KW |

| Max Temp | 1500°C |

| Lokacin narkewa | 2-3 min. |

| Gas mai kariya | Argon / Nitrogen |

| Daidaiton Temp | ±1°C |

| Iya (Gold) | 24K: 2.0Kg, 18K: 1.55Kg, 14K: 1.5Kg, 925Ag: 1.0Kg |

| Ƙarƙashin Ƙarfafawa | Farashin 242CC |

| Matsakaicin girman flask | 5 "x12" |

| Vacuum Pump | Babban ingancin injin famfo |

| Aikace-aikace | Zinariya, K zinari, azurfa, jan karfe da sauran abubuwan gami |

| Hanyar aiki | Maɓalli ɗaya yana gama duk aikin simintin |

| Nau'in sanyaya | Mai sanyin ruwa (ana siyar dashi daban) ko Ruwan Gudu |

| Girma | 800*600*1200mm |

| Nauyi | kusan 230kg |

Nuni samfurin

Take: Juyin Halittar Fasahar Simintin Kayan Adon Zinariya: Daga Tsoffin Dabarun Zuwa Ƙirƙirar Zamani

Shekaru da yawa, kayan ado na zinariya sun kasance alamar dukiya, matsayi da kyau. Daga tsoffin wayewa zuwa salon zamani, fara'a na zinariya ya kasance iri ɗaya. Ɗaya daga cikin mahimman matakai don ƙirƙirar kayan ado na zinariya shine simintin gyare-gyare, wanda ya samo asali sosai a tsawon lokaci. A cikin wannan shafin yanar gizon, za mu bincika tafiya mai ban sha'awa na fasahar simintin kayan adon gwal, tun daga farkon abubuwan da suka faru zuwa sabbin sabbin abubuwa na yau.

Fasahar Dadi: Haihuwar Simintin Zinare

Za a iya gano tarihin simintin zinari zuwa tsoffin wayewa kamar Masar, Mesofotamiya, da Sin. Waɗannan masu sana'a na farko sun haɓaka dabarun yin simintin gyare-gyare ta hanyar amfani da sassauƙan ƙira da aka yi da yumbu, yashi, ko dutse. Tsarin ya haɗa da dumama gwal har sai ya kai ga narkakken yanayi sannan a zuba shi a cikin gyare-gyaren da aka shirya don ƙirƙirar kayan ado.

Duk da yake waɗannan tsoffin hanyoyin sun kasance masu tasowa don lokacinsu, an iyakance su cikin daidaito da rikitarwa. Abubuwan kayan ado waɗanda ke haifar da sau da yawa suna da ƙaƙƙarfan bayyanar da ɗanɗano, ba su da cikakkun bayanai da ƙira masu ƙima waɗanda ke nuna kayan ado na zinariya na zamani.

Ci gaban Tsakiyar Tsakiya: Yunƙurin Simintin Kakin Kakin Da Ya Bace

A lokacin Tsakiyar Tsakiyar, manyan ci gaba a fasahar simintin zinare sun faru tare da haɓaka fasahar simintin kakin zuma. Wannan hanyar ta kawo sauyi a tsarin simintin gyare-gyare, wanda ya baiwa masu sana'a damar ƙirƙirar ƙarin hadaddun kayan ado dalla-dalla.

Tsarin simintin kakin da ya ɓace ya ƙunshi ƙirƙirar ƙirar kakin zuma na ƙirar kayan ado da ake so, wanda sai a lulluɓe shi a cikin wani nau'i na filasta ko yumbu. An yi zafi da ƙura, yana haifar da kakin zuma ya narke kuma ya ƙafe, yana barin wani rami a cikin siffar asali na kakin zuma. Daga nan aka zuba gwal da aka narkakkar a cikin rami, tare da samar da daidaitaccen samfurin kakin zuma.

Wannan fasaha ta nuna babban ci gaba a cikin fasahar simintin zinare, ta baiwa masu sana'a damar kera kayan adon da ke da sarkakkiya, aikin filigree mai laushi, da kyawawan laushi waɗanda a baya ba za a iya cimma su ba.

Juyin Juyin Masana'antu: Tsarin Simintin Kayan Aiki

Juyin juya halin masana'antu ya kawo yunƙurin ci gaban fasaha wanda ya kawo sauyi kan ayyukan masana'antu a masana'antu daban-daban, gami da samar da kayan ado. A cikin wannan lokacin, an gabatar da tsarin simintin gyaran gyare-gyare na injina, wanda ke ba da damar samar da kayan adon gwal da yawa.

Ɗayan mahimman sabbin abubuwa shine haɓaka injin simintin simintin centrifugal, wanda yayi amfani da ƙarfin centrifugal don rarraba narkakkar gwal a daidai gwargwado. Wannan tsari mai sarrafa kansa yana ƙaruwa da inganci da daidaiton simintin gwal, yana haifar da mafi girma fitarwa da ƙarin daidaitattun kayan ado.

Ƙirƙirar zamani: ƙirar dijital da bugu na 3D

A cikin 'yan shekarun nan, fitowar ƙirar dijital da fasahar bugu na 3D sun canza yanayin simintin kayan adon gwal. Waɗannan sabbin sababbin abubuwa sun canza yadda ake ƙirƙirar ƙirar kayan ado da kuma fassara su zuwa abubuwa na zahiri.

Software na ƙira na dijital yana ba masu zanen kayan ado damar ƙirƙirar ƙirar 3D mai rikitarwa tare da daidaici da dalla-dalla da ba a taɓa ganin irinsa ba. Ana iya canza waɗannan samfuran dijital su zama samfura na zahiri ta hanyar amfani da fasahar bugu na 3D, wanda ke gina shingen kayan adon ta Layer ta amfani da kayayyaki iri-iri, gami da kakin zuma don yin simintin gyare-gyare.

Amfani da bugu na 3D a cikin simintin kayan adon zinare yana buɗe sabbin damammaki don ƙirƙirar ƙira mai sarƙaƙƙiya da ƙirar ƙira waɗanda a baya ba za a iya cimma su ta hanyoyin simintin gargajiya ba. Har ila yau, fasahar tana daidaita tsarin samfuri da samarwa, da rage lokutan gubar da kuma ba da damar yin gyare-gyare cikin sauri na ƙirar kayan ado.

Bugu da ƙari, ci gaba a cikin fasahar ƙarfe da haɗin gwal sun sauƙaƙe haɓaka sabbin kayan haɗin gwal tare da ingantattun kaddarorin kamar ƙara ƙarfi, dorewa, da canza launi. Waɗannan sabbin kayan haɗin gwiwar suna faɗaɗa damar ƙirƙira don masu zanen kayan ado da masana'anta, suna ba su damar tura iyakokin kayan ado na kayan ado na gargajiya na gwal.

Makomar fasahar simintin kayan ado na zinariya

Yayin da fasaha ke ci gaba da ci gaba, makomar simintin gyare-gyaren kayan adon gwal na riƙe da dama mai ban sha'awa. Ana sa ran fasahohin da suka kunno kai kamar masana'antar ƙari da ci-gaba na mutum-mutumi za su ƙara kawo sauyi kan tsarin simintin, da kawo sabbin matakan daidaito, inganci da keɓancewa.

Bugu da ƙari, haɗa basirar ɗan adam da na'ura algorithms na koyon injin cikin ƙirar kayan ado da samar da ayyukan aiki yana da yuwuwar haɓaka aikin simintin, rage sharar kayan abu, da haɓaka gabaɗayan ingancin kayan adon da aka gama.

A ƙarshe, haɓakar fasahar simintin kayan adon zinare shaida ce ga hazaka da sabbin ƴan fasaha da masu fasaha a tsawon tarihi. Daga tsohuwar dabarar simintin kakin zuma da aka rasa zuwa abubuwan al'ajabi na zamani na ƙirar dijital da bugu na 3D, fasahar simintin zinare na ci gaba da haɓakawa don biyan buƙatun lokuta masu canzawa.

Da yake kallon nan gaba, a bayyane yake cewa haɗuwa da fasahar gargajiya da fasaha na fasaha za ta ci gaba da tsara yanayin simintin kayan ado na zinariya, samar da damar da ba ta ƙare ba don ƙirƙira, gyare-gyare da inganci a cikin kyawawan kayan ado na duniya.

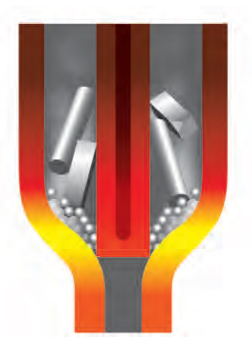

Na'uran simintin matsi na matsa lamba:

1. Graphite crucible

2. Ceramic gasket

3. Jaket ɗin yumbu

4. Matsakaicin hoto

5. Thermocouple

6. Nada mai zafi

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur