HUKUNCIN WIRE

GASKIYA TUSHEN ILMI

Mene ne Waya Bonding?

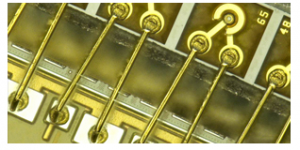

Haɗin waya shine hanyar da ake haɗa tsayin ƙaramin diamita mai laushi na ƙarfe zuwa saman ƙarfe mai dacewa ba tare da amfani da solder, juzu'i ba, kuma a wasu lokuta tare da amfani da zafi sama da digiri 150 na Celsius. Karafa masu laushi sun haɗa da Zinariya (Au), Copper (Cu), Azurfa (Ag), Aluminum (Al) da kuma gami irin su Palladium-Silver (PdAg) da sauransu.

Fahimtar Dabarun Haɗin Waya da Tsari don Aikace-aikacen Majalisar Lantarki na Micro Electronics.

Dabaru / Tsari Tsari: Ribbon, Kwallon Thermosonic & Ultrasonic Wedge Bond

Haɗin waya shine hanyar yin haɗin kai tsakanin haɗaɗɗiyar da'irar (IC) ko makamancin na'urar semiconductor da fakitin ko firam ɗin jagora yayin masana'anta. Har ila yau, ana amfani da shi fiye da yanzu don samar da haɗin wutar lantarki a cikin ɗakunan baturi na lithium-ion. Wire bonding ana daukarsa a matsayin mafi tsada-tasiri da sassauƙa na fasahar haɗin gwiwar microelectronic da ke samuwa, kuma ana amfani dashi a yawancin fakitin semiconductor da aka samar a yau. dabaru ne da dama na haɗa waya, waɗanda suka haɗa da:Thermo-Compression Wire Bonding:

Thermo-compression waya bonding (hade da yiwuwar saman (yawanci Au) tare a ƙarƙashin wani clamping ƙarfi tare da high interface yanayin zafi, yawanci fiye da 300 ° C, don samar da walda), da farko an ɓullo da a cikin 1950 ta don microelectronics interconnects, duk da haka wannan ya kasance. da sauri maye gurbinsu da Ultrasonic & Thermosonic bonding a cikin 60 ta a matsayin rinjaye interconnect fasaha. Thermo-matsi bonding ne har yanzu a amfani ga alkuki aikace-aikace a yau, amma gaba ɗaya kauce wa da masana'antun saboda high (sau da yawa lalacewa) dubawa yanayin zafi da ake bukata domin yin nasara bond.Ultrasonic Wedge Waya bonding:

A cikin shekarun 1960's Ultrasonic wedge wire bonding ya zama babbar hanyar haɗin kai. Aikace-aikacen babban girgizar mitar (ta hanyar transducer resonating) zuwa kayan aikin haɗin gwiwa tare da ƙarfi na lokaci guda, an ba da izinin walda wayoyi na Aluminum da Zinariya a zafin daki. Wannan Ultrasonic vibration taimaka a cire contaminants (oxides, impurities, da dai sauransu) daga bonding saman a farkon bonding sake zagayowar, da kuma inganta intermetallic girma don kara bunkasa da kuma karfafa bond. Hankula mitoci ga bonding ne 60 – 120 KHz. The ultrasonic wedge dabara yana da biyu main tsari fasahar: Large (nauyi) waya bonding for>100µm diamita wiresFine (ƙananan) waya bonding for <75µm diamita wiresMisalan na hankula Ultrasonic bonding hawan keke za a iya samu a nan. don waya mai kyau kuma a nan don babban waya.Ultrasonic wedge wire bonding yana amfani da takamaiman kayan aiki na haɗin gwiwa ko "Wedge," yawanci ana gina shi daga Tungsten Carbide (don Aluminum waya) ko Titanium Carbide (don Wayar Zinariya) dangane da buƙatun tsari da diamita na waya; Hakanan ana samun yumbu tipped wedges don aikace-aikace daban-daban. Thermosonic Wire Bonding:

Inda ake buƙatar ƙarin dumama (yawanci don wayar Zinariya, tare da haɗin haɗin gwiwa a cikin kewayon 100 – 250°C), ana kiran tsarin haɗin haɗin waya na Thermosonic. Wannan yana da babban fa'ida a kan tsarin matsi na gargajiya na gargajiya, kamar yadda ake buƙatar ƙananan yanayin zafi (Au bonding a dakin zafin jiki an ambaci amma a aikace ba shi da tabbas ba tare da ƙarin zafi ba).Thermosonic Ball Bonding:

Wani nau'i na haɗin waya na Thermosonic shine Ball Bonding (duba zagayowar haɗin ball a nan). Wannan hanya tana amfani da kayan aikin haɗin gwiwa na yumbu akan ƙirar ƙira na gargajiya don haɗa mafi kyawun halaye a cikin matsi da zafi da ultrasonic bonding ba tare da lahani ba. Thermosonic vibration yana tabbatar da zafin jiki na dubawa ya kasance ƙasa kaɗan, yayin da haɗin farko na farko, haɗin ƙwallon ƙwallon zafi yana ba da damar waya da haɗin gwiwa na biyu don sanya su a kowace hanya, ba a cikin layi tare da haɗin farko ba, wanda shine ƙuntatawa a haɗin haɗin waya na Ultrasonic. . Domin atomatik, high girma yi, ball bonders ne da yawa sauri fiye da Ultrasonic / Thermosonic (Wedge) bonders, yin Thermosonic ball bonding rinjaye interconnect fasaha a cikin microelectronics na karshe 50+ shekaru. Ribbon bonding:

Haɗin ribbon, ta amfani da kaset ɗin ƙarfe na lebur, ya kasance mafi rinjaye a cikin RF da Microwave Electronics tsawon shekaru da yawa (ƙiddigar samar da gagarumin ci gaba a asarar sigina [tasirin fata] tare da waya zagaye na gargajiya). Ƙananan ribbons na Zinariya, yawanci har zuwa faɗin 75µm da kauri 25µm, ana haɗa su ta hanyar tsarin Thermosonic tare da babban kayan haɗin kai mai fuska. Abubuwan da ake buƙata don ƙananan madauki, babban haɗin haɗin haɗin gwiwa ya karu.

Menene zinariya bonding waya?

Haɗin wayar zinari shine tsarin da ake haɗa wayar zinari zuwa maki biyu a cikin taro don samar da haɗin kai ko hanyar da za a iya sarrafa wutar lantarki. Heat, ultrasonics, da karfi duk suna aiki don samar da abubuwan da aka makala don waya ta zinare.Tsarin ƙirƙirar abin da aka makala ya fara tare da samuwar ƙwallon zinari a ƙarshen kayan haɗin waya, capillary. Ana danna wannan ball akan farfajiyar taro mai zafi yayin da ake amfani da nau'ikan takamaiman takamaiman aikace-aikacen da mitar 60kHz - 152kHz na motsi na ultrasonic tare da kayan aiki.Da zarar an yi haɗin gwiwa na farko, za a yi amfani da waya a cikin tsari mai ƙarfi. yadda za a samar da siffar madauki mai dacewa don ma'auni na taron. Haɗin na biyu, wanda galibi ana kiransa ɗinki, yana samuwa akan ɗayan saman ta hanyar danna ƙasa tare da waya da yin amfani da manne don yaga wayar a haɗin.

Haɗin wayar zinare yana ba da hanyar haɗin kai a cikin fakitin da ke da wutar lantarki sosai, kusan tsari na girma fiye da wasu masu siyarwa. Bugu da ƙari, wayoyi na zinariya suna da babban juriya na oxygenation idan aka kwatanta da sauran kayan waya kuma suna da laushi fiye da yawancin, wanda ke da mahimmanci ga wurare masu mahimmanci.

Hakanan tsarin zai iya bambanta dangane da bukatun taron. Tare da kayan aiki masu mahimmanci, za a iya sanya ƙwallon zinari a kan yanki na biyu na haɗin gwiwa don ƙirƙirar haɗin gwiwa mai ƙarfi da haɗin gwiwa "mai laushi" don hana lalacewar farfajiyar ɓangaren. Tare da matsatsun wurare, ana iya amfani da ƙwallon guda ɗaya azaman mafari don ɗaure biyu, ƙirƙirar haɗin “V” mai siffa. Lokacin da haɗin waya ya buƙaci ya zama mai ƙarfi, ana iya sanya ball a saman ɗinki don samar da haɗin tsaro, ƙara kwanciyar hankali da ƙarfin wayar. Yawancin aikace-aikace daban-daban da bambance-bambancen haɗin haɗin waya kusan ba su da iyaka kuma ana iya samun su ta hanyar amfani da software mai sarrafa kansa akan tsarin haɗin waya na Palomar.

Ci gaban haɗin waya:

An gano haɗin waya a Jamus a cikin shekarun 1950 ta hanyar duban gwaji na sa'a kuma daga baya an haɓaka shi zuwa tsari mai sarrafa gaske. A yau ana amfani da shi da yawa don haɗa haɗin gwiwar semiconductor kwakwalwan kwamfuta zuwa fakitin jagora, faifan faifai zuwa na'urori masu haɓakawa, da sauran aikace-aikacen da yawa waɗanda ke ba da damar abubuwan yau da kullun su zama ƙarami, "mafi wayo", kuma mafi inganci.

Aikace-aikacen Wayoyin Daɗi

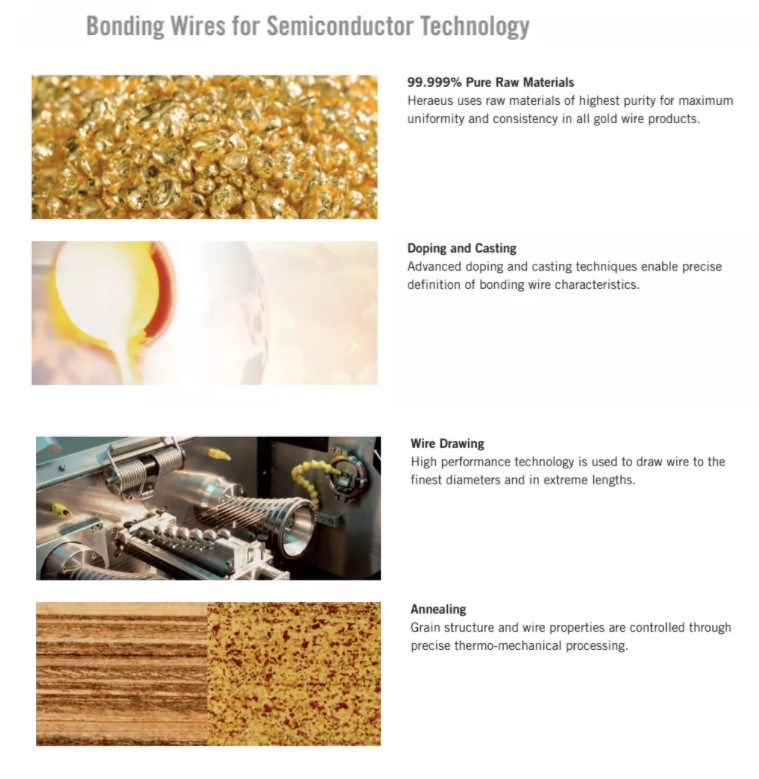

Ƙara ƙararrawa a cikin kayan lantarki ya haifar

a bonding wayoyi zama muhimman abubuwan da ke cikin

lantarki majalisai.

A saboda wannan dalili lafiya da ultrafine bonding wayoyi na

Ana amfani da zinariya, aluminum, jan karfe da palladium. Mafi girma

ana yin buƙatu akan ingancin su, musamman ma dangane da su

zuwa daidaitattun kaddarorin waya.

Dangane da abubuwan sinadaran su da takamaiman

Properties, da bonding wayoyi suna dace da bonding

dabara zaba da kuma atomatik bonding inji kamar yadda

da kuma kalubale daban-daban a cikin fasahar hadawa.

Heraeus Electronics yana ba da kewayon samfura da yawa

don aikace-aikace daban-daban na

Masana'antar kera motoci

Sadarwa

Semiconductor masana'antun

Masana'antar kayan masarufi

Ƙungiyoyin samfur na Heraeus Bonding Wire sune:

Wayoyin haɗin gwiwa don aikace-aikace a cikin filastik cike

kayan lantarki

Aluminum da aluminum gami gami da wayoyi don

aikace-aikacen da ke buƙatar ƙananan zafin aiki

Copper bonding wayoyi a matsayin fasaha da kuma

tattalin arziki madadin zuwa zinariya wayoyi

Ƙarfe na haɗin gwiwa mai daraja da mara daraja don

haɗin lantarki tare da manyan wuraren hulɗa.

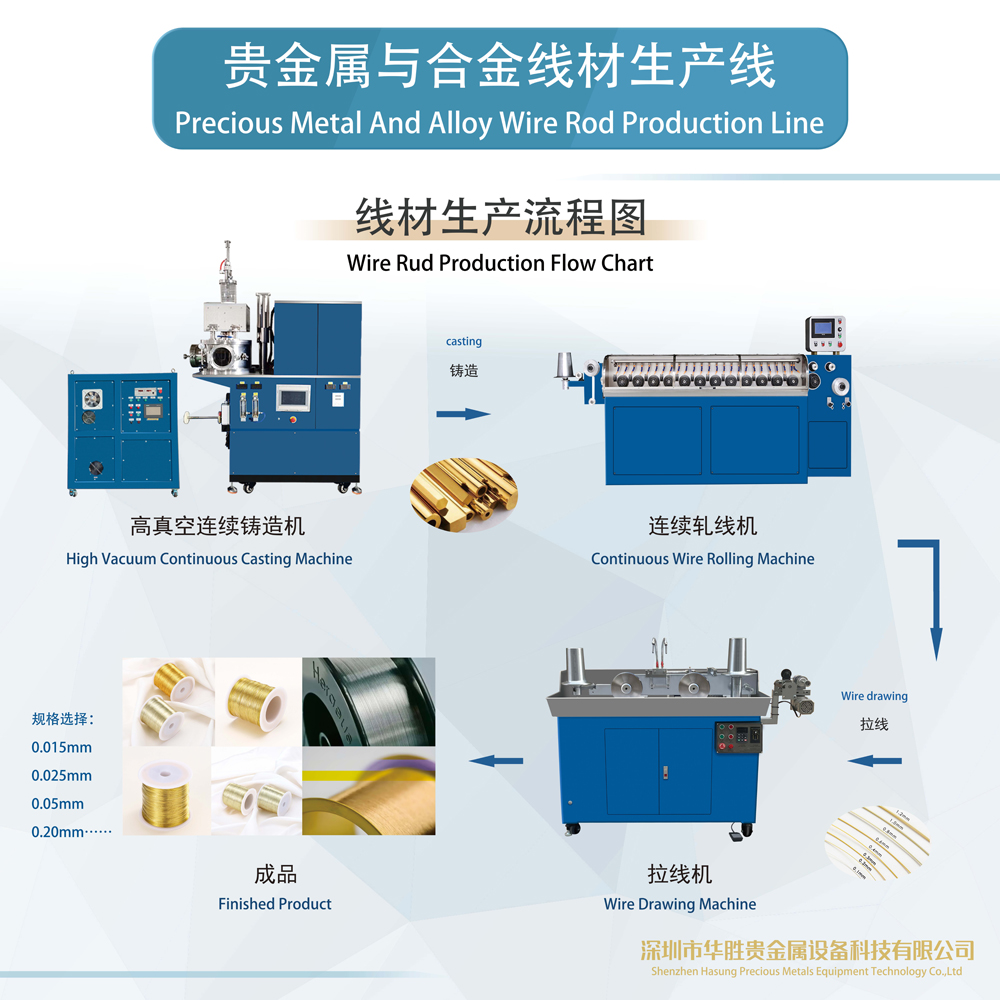

Layin Samar da Wayoyi na Bonding

Lokacin aikawa: Jul-22-2022