Injin Cimin Matsala

Injin simintin HASUNG sun dace don narke da jefa karafa na yanayin zafi mai narkewa. Bisa ga samfurin, za su iya jefa da kuma narke zinariya, Karat zinariya, azurfa, jan karfe, gami da TVC, VPC, VC jerin, kuma karfe, platinum, palladium tare da MC jerin.

Babban ra'ayin HASUNG injin matsi na matsi shine rufe murfin da fara dumama da zarar injin ya cika da kayan ƙarfe.

Za a iya zaɓar zafin jiki da hannu.

An narkar da kayan a ƙarƙashin iskar gas mai kariya (argon/nitrogen) don guje wa oxidation. Ana iya ganin hanyar narkewa cikin sauƙi ta taga mai kallo. Ana sanya ƙugiya a tsakiya a cikin ɓangaren sama na rufaffiyar ɗakin alumini mai matse iska a cikin tsakiyar spool ɗin shigar. A halin da ake ciki ana sanya flask ɗin mai dumama fom ɗin simintin gyare-gyare a cikin ƙananan ɓangaren ɗakin injin bakin karfe. An karkatar da ɗakin dattin kuma an kulle shi a ƙarƙashin crucible. Don aikin simintin gyare-gyaren ana saita crucible ƙarƙashin matsi kuma a ƙarƙashin matsi. Bambancin matsin lamba yana jagorantar ƙarfen ruwa zuwa mafi kyawun ramification na sigar. Ana iya saita matsa lamba da ake buƙata daga 0.1 Mpa zuwa 0.3 Mpa.

Tushen yana nisantar kumfa da porosity.

Bayan haka an buɗe ɗakin datti kuma za'a iya fitar da flask ɗin.

Na'urorin TVC, VPC, VC suna sanye da abin ɗaukar flask wanda ke tura flask ɗin zuwa caster. Wannan yana sauƙaƙa cire flask ɗin.

Injin jeri na MC suna karkatar da nau'in simintin ƙarfe, tare da juyawa digiri 90 na musamman don yin simintin ƙarfe mai zafin jiki. Ya maye gurbin simintin gyare-gyare na centrifugal.

-

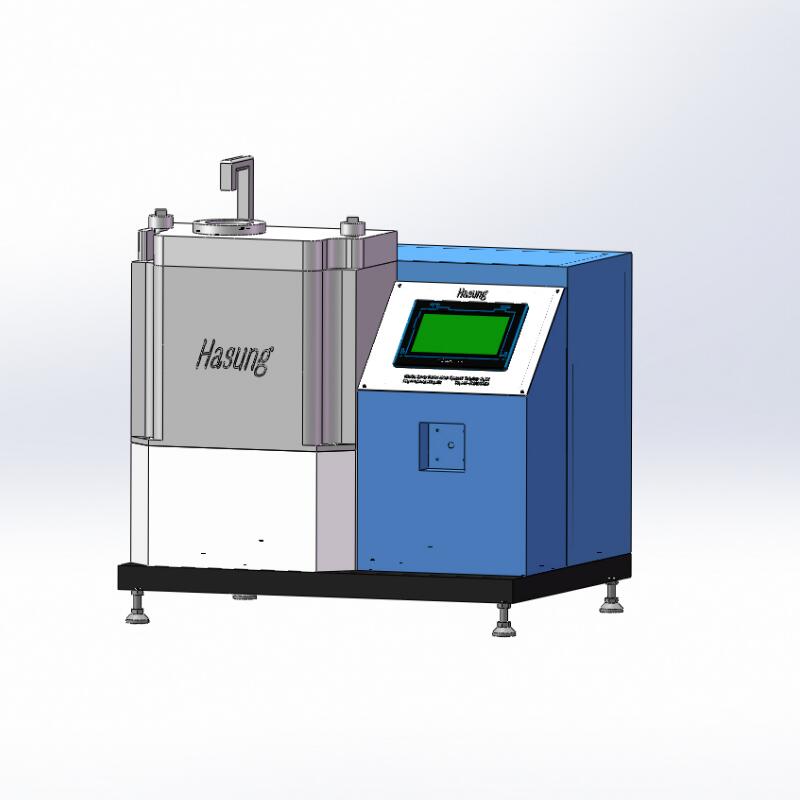

VCT Series Vacuum Matsi Matsi Machine tare da PLC Touch Screen

Injin matsa lamba na gaba na Hasung shine injin ku na gaba don ƙirƙirar inganci.

1 Tallafi da flange da flange ba tare da flange ba

2. Kyakkyawan saurin narkewa, ceton makamashi

3. Inert Gas - tare da kyawawan kayan cikawa

4. Daidaitaccen ma'auni tare da ingantaccen fahimtar matsi

5. Sauƙi don kulawa

6. Daidaitaccen lokacin matsa lamba

7. Ciwon kai - Taiwan Weinview PLC touch panel auto-tuning

8. Sauƙi don aiki, botton ɗaya don gama duk aikin simintin9. Bayan yanayin ba tare da iskar shaka ba

10. Zafi mai canzawa don asarar zinare

11. Matsakaicin matsa lamba, matsa lamba argon, zafin jiki, lokacin zubewa, lokacin matsa lamba, lokacin injin.

-

VCTV Series Jewelry Vacuum Matsi Matsi Machine tare da Vibration System

Injin matsa lamba na gaba na Hasung shine injin ku na gaba don ƙirƙirar inganci.

1. Hanyoyi biyu don flask tare da flange da flange ba tare da flange ba

2. Tsarin girgiza don simintin gyare-gyare mai kyau

3. Ƙarin hadawa don kyakkyawan rabuwa na zinariya

4. Kyakkyawan saurin narkewa, ceton makamashi

5. Inert Gas - tare da kyawawan kayan cikawa

6. Daidaitaccen ma'auni tare da ingantaccen fahimtar matsi

7. Sauƙi don kulawa

8. Daidaitaccen lokacin matsa lamba

9. Binciken kai - Japan Mitsubishi PLC touch panel auto-tuning

10. Sauƙi don aiki, tudu ɗaya don gama duk aikin simintin11. Bayan yanayin ba tare da iskar shaka ba

12. Zafi mai canzawa don asarar zinare

13. Vacuum matsa lamba, matsa lamba argon, zafin jiki, lokacin zubarwa, lokacin matsa lamba, lokacin motsa jiki, lokacin rawar jiki, lokacin riƙewar jijjiga za a iya saita shi, Shirye-shiryen flask tare da flange, shirin flask ba tare da flange ba, duka suna samuwa, yanayin atomatik da yanayin manual suna samuwa.

-

TVC Series Induction Vacuum Matsayin Casting Machine don Zinariya Copper

Cikakkun Injin Matsayin Matsi Na atomatik

Sabuwar fasaha don haɓaka sakamakon simintin

The Hasung Casting System

1.Rufe murfin ta atomatik, duk yana aiki ta atomatik don yin simintin gyare-gyare gabaɗaya yana haɓaka kwararar kayan aiki da ciko mold

2.Castings suna nuna mafi girma kuma mafi daidaituwa

3.Porosity yana raguwa sosai

4. Juriya Max. 4 sanduna suna matsa lamba.

5. SBS sabon tsarin ba tare da yin amfani da gaskets ba, ajiye farashi.

6.Castings suna da mafi girma danniya da elasticity Properties, sa su sauki aiwatar da kara.

7. Easy touch aiki tare da amfani allon siga

8. Akwai shirye-shirye 100.

-

VPC Series Vacuum Matsi Na'ura Simintin gyaran kafa don kayan ado

Matsi akan Injin Casting Vacuum

VCT dangi ne na matsin lamba akan injinan simintin ƙera da aka ƙera don biyan mafi tsananin buƙatu a cikin asarar simintin kakin zuma na zinari, K-zinariya, jan karfe, tagulla, gami. Ana amfani da su akai-akai dangane da firinta na 3d don yin simintin kai tsaye don samun sassan ƙarfe na farko na abubuwa masu rikitarwa.

Wannan dangin injina yana aiki tare da sabon ra'ayi na ɗaki biyu na juyi. Wannan sabon tsarin yana ba da fa'idodi da yawa idan aka kwatanta da tsarin tsotsa ɗaki ɗaya na gargajiya a halin yanzu da ake samu a kasuwa.

A cikin VCT, ɗakin narkewa da ɗakin flask ba su da hannu gaba ɗaya: yayin da ake yin simintin, injin zai iya sarrafa allurar ƙarfe a cikin ƙirar ta amfani da matsi daban-daban yayin zubarwa. Wannan yana haifar da yin allura cikin sauri idan aka kwatanta da sauƙaƙan nauyin nauyi tare da fa'idar jefa abubuwa a ƙananan zafin jiki. Wannan zai haifar da mafi kyawun ƙarewa da rage raguwar sassan simintin.Zagayowar simintin yana ɗaukar 'yan mintuna kaɗan kawai kuma, yayin da flask ɗin da ta gabata ke yin sanyi a cikin iskar kariya don babu iskar oxygen, za'a iya loda cajin na gaba a cikin crucible kuma ya narke, don haka ya mamaye zagaye biyu don babu ɓata lokaci.

Injin yana da cikakken atomatik, yana nuna tsarin sa ido na tushen PC don siyan sigogin tsari da sarrafa bayanan samarwa, tare da sauƙin gyara shirye-shiryen jefar da suka dace da nau'ikan gami da yawa.

Wannan na'ura mai juyi ita ce haɗin injiniya mafi ci gaba da ƙwarewar shekaru a cikin yin simintin gyare-gyare wanda Hasung kawai zai kawo cikin masana'anta.

-

Hasung T2 Kayan Adon Wuta na Matsayin Simintin Simintin Gyaran Mashin

Injin simintin matsi na gaba na Hasung shine injin ku na gaba don ƙirƙirar inganci.

Amfanin T2:

1. Bayan yanayin ba tare da iskar shaka ba

2. Zafi mai canzawa don asarar zinare

3. Ƙarin hadawa don kyakkyawan rabuwa na zinariya

4. Kyakkyawan saurin narkewa

5. De-Gas - tare da kyawawan kayan cikawa don karafa

6. Daidaitaccen ma'auni na allura biyu tare da ingantaccen fahimtar matsi

7. Sauƙi don kiyayewa yayin yin simintin

8. Daidaitaccen lokacin matsa lamba

9. Binciken kai - PID auto-tuning

10. Ƙwaƙwalwar siga don mafi kyawun simintin gyare-gyare

11. Tsarin Simintin Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa ) - max. matsa lamba 0.3MPa tare da tankin gas na ciki

12. Sauya Gas Single Gas (Argon)

13. Memorin Shirin 100 memories

14. Sarrafa musamman tsara microprocessor iko. Sarrafa zafin jiki ta PID tare da daidaiton digiri +/-1 centigrade.

15. Dumama Induction dumama (tare da aikin motsa jiki na musamman da aka ƙera). -

Mini Vacuum Matsayin Casting Machine don Platinum Palladium Karfe Zinare Azurfa

Fa'idodin kayan aikin Hasung Precious Metals SVC/MC

Siffofin SVC / MC sune injunan simintin simintin gyare-gyaren da suka dace da nau'ikan aikace-aikace don simintin ƙarfe - da zaɓin zaɓi waɗanda aka ɗauka ba su dace da juna ba har zuwa yanzu. Don haka, yayin da jerin MC an tsara su ne a matsayin na'ura mai zafi mai zafi don yin simintin ƙarfe, palladium, platinum da dai sauransu (max. 2,100 ° C), manyan flasks kuma suna sa ya dace da samar da simintin gyare-gyare na tattalin arziki a cikin zinariya, azurfa, jan karfe. karfe, gami da sauran kayan.

Injin yana haɗa tsarin matsi na banbance-banbancen ɗaki biyu tare da tsarin karkatarwa. Ana samun tsarin yin simintin ta hanyar jujjuya gaba ɗaya naúrar simintin narke da 90°. Ɗaya daga cikin fa'idodin tsarin karkatarwa shine amfani da graphite mai tsadar tattalin arziki ko yumbu (ba tare da ramuka da sandunan rufewa ba). Waɗannan suna da tsawon rayuwar sabis. Wasu gami, irin su jan karfe beryllium, da sauri suna haifar da ƙugiya mai ramuka da sandunan rufewa su zama marasa ƙarfi don haka ba su da amfani. Saboda haka, yawancin simintin gyaran kafa ya zuwa yanzu sun sarrafa irin waɗannan allunan kawai a cikin buɗaɗɗen tsarin. Amma wannan yana nufin ba za su iya zaɓar inganta aikin ba tare da wuce gona da iri ko vacuum.

-

Na'ura mai karkatar da matsa lamba don Platinum Palladium Zinariya Karfe

Fa'idodin Hasung Precious Metals Equipment

Samfurin yana da launi iri ɗaya kuma babu rarrabuwa:

An rage girman porosity, kuma yawancin ya fi girma kuma yana da yawa, yana rage aikin aiki bayan aiki da rage hasara.

Ingantacciyar ruwa mai ƙarfi da ciko mold, ƙarancin sha'awa:

Jijjiga yana inganta kwararar kayan aiki, kuma tsarin kayan ya fi dacewa. Inganta ciko siffar kuma rage haɗarin fashewar zafi

An rage girman hatsi zuwa 50%:

Ƙarfafa tare da mafi kyawun tsari kuma mafi daidaituwa

Ingantattun kaddarorin kayan aiki masu inganci:

Ƙarfin ƙarfi da elasticity yana ƙaruwa da 25%, kuma ana inganta aikin sarrafawa na gaba.

Tambaya: Menene Hanyar Simintin Wuta?

Simintin saka hannun jari, waɗanda galibi ana kiransu simintin ɓataccen abu, sassan ƙarfe ne waɗanda aka samar ta hanyar simintin saka hannun jari. Wannan tsari mai kashewa da kayan aikin da yake samarwa sun shahara sosai ga aikace-aikace marasa adadi a masana'antu da yawa. Wannan ya faru ne saboda gaskiyar cewa tsarin simintin saka hannun jari yana ba da damar ƙirƙirar sassa masu rikitarwa tare da halaye na musamman da daidaito a cikin kewayon kayan da girma. Koyaya, idan wani yanki yana buƙatar ƙaƙƙarfan cikakkun bayanai ko yanke ƙasa, ana ƙarfafa kayan ta hanyar fiber ko waya, ko kama iska yana da matsala, ana amfani da takamaiman nau'in hanyar simintin saka hannun jari. Wannan dabarar simintin saka hannun jari ba wata bace illa hanyar simintin gyaran kafa, wadda ta haifar da simintin gyaran kafa. Menene vacuum simintin gyaran kafa? Ci gaba da karantawa don ganowa.

Menene Vacuum Investment Castings?

Vacuum simintin gyare-gyare sune sassa na ƙarfe waɗanda aka samar ta hanyar vacuum simintin. Sun bambanta da simintin saka hannun jari na yau da kullun saboda dabarun da ake amfani da su don ƙirƙirar waɗannan sassan ƙarfe. Tsarin yana farawa ta hanyar sanya wani yanki na filasta a cikin ɗaki mara nauyi. Sai injin ya zana narkakkar karfen zuwa cikin injin. A ƙarshe, ana ƙarfafa simintin gyare-gyare a cikin tanda kuma an cire samfurin don sakin samfurin ƙarshe.

Idan kuna da aikin da ke buƙatar simintin saka hannun jari mai inganci don kayan ado ko wasu karafa, za mu iya samar muku da su. Anan a Hasung, muna amfani da nau'ikan nau'ikan nauyi da kuma hanyoyin yin simintin ƙarfe don samar da gwal, azurfa, platinum, abubuwan ƙarfe waɗanda ke da iyaka. Ƙwararrun shekarun mu marasa ƙima a cikin waɗannan hanyoyin guda biyu suna ba da tabbacin cewa za mu iya samar da mafifici ko kusa da sassan sifa waɗanda ke buƙatar ƙaramin aiki ko ƙarewa. Sami simintin gyare-gyaren saka hannun jari da kuke buƙata, wanda aka kawo akan lokaci kuma akan farashi mai gasa, ta hanyar tuntuɓar mu a yau!

Tambaya: Yadda za a jefa kayan ado?

Yin simintin kayan ado tsari ne na kera kayan adon da ke tattare da zub da garin karfen ruwa a cikin gyambo. Yawancin lokaci ana kiransa simintin kakin zuma da ya ɓace saboda an ƙirƙiri simintin simintin ta amfani da samfurin kakin zuma wanda aka narke don barin ɗaki mara ƙarfi a tsakiyar ƙirar. An yi amfani da wannan fasaha tsawon dubban shekaru, kuma har yanzu ana amfani da ita sosai a yau ta hanyar manyan masu sana'a da masu sana'a na gida don yin daidaitattun kayan ado na asali. Idan kuna sha'awar ƙirƙirar kayan adon ku ta amfani da dabarar simintin, bi waɗannan matakan don yadda ake jefa kayan ado.

1. Kirkirar Kwayoyin Ku

1) Zana wani yanki na kakin ƙira mai wuya a cikin siffar da kuke so. Fara mai sauƙi a yanzu, saboda hadaddun gyare-gyare sun fi wuya a kiyaye tare da farko. Sami yanki na kakin ƙira kuma yi amfani da madaidaicin wuka, Dremel, da duk wani kayan aiki da ake buƙata don yin samfurin kayan adon ku. Ko wane irin siffa da kuka yi yanzu zai zama sifar gunkin da kuka gama.

Kuna yin ainihin kwafin kayan adon ku na ƙarshe.

Yin amfani da kayan adon da kuke so azaman samfuri zai taimaka muku tsara mafi kyawun guda lokacin da kuka fara farawa.

2) Haɗa 3-4 "sprues," wayoyi na kakin zuma waɗanda za su samar da tashar don kakin zuma ya narke daga baya. Yin amfani da wasu ƙarin kakin zuma, ƙera dogayen da yawa, wayoyi daga cikin kakin zuma kuma haɗa su zuwa ƙirar ta yadda duk su ja da baya. Wannan ya fi sauƙi a fahimta lokacin da kuka ga tsarin gaba ɗaya-wannan kakin zuma za'a rufe shi da filasta, sannan ya narke don yin sigar siffa mara kyau. Sai ki cika guraren da azurfa. Idan ba ku yi sprues ba, kakin zuma mai narkewa ba zai iya fita ya yi wuri mara kyau ba.

Don ƙananan guda, kamar zobe, ƙila za ku buƙaci sprue ɗaya kawai. Manyan guda, kamar ƙullun bel, na iya buƙatar har zuwa goma.

Duk sprues su hadu a wuri guda. Za su buƙaci a haɗa su zuwa tushen sprue.

3) Haɗa mold zuwa tushen sprue ta amfani da ɗan narkeccen roba. Ganyayyaki duk suna haɗuwa tare, kuma kuna haɗa ƙirar zuwa tushen sprue inda duk sprues ke haɗuwa. Wannan yana ba da damar kakin zuma ya narke ta ƙasan tushe kuma ya bar ƙirar.

4) Sanya flask a saman tushen sprue, tabbatar da cewa kuna da inci kwata tsakanin bangon flask da samfurin. Flask ɗin babban silinda ne wanda ke zamewa a saman gindin sprue.

2. Zuba Jari

1) Aminta samfurin kakin zuma yana tsayawa zuwa kasan filin simintin gyare-gyare, ta amfani da ƙarin narkewar kakin zuma. Samfurin ya kamata a ba da shi a cikin flask. An shirya don tsarin simintin kayan ado.

Lura: A cikin bidiyon, ɓangarorin azurfa da suka wuce sauran kayan kayan ado suna tafiya tare da bel ɗin bel. Ba ƙarin sprues ba ne ko ƙari masu mahimmanci.

2) Haɗa busassun kayan aikin gypsum plaster na tushen saka hannun jari da ruwa, kamar yadda umarnin masana'anta. Bi umarnin kowane nau'in saka hannun jari da kuka zaɓa don siya-ya kamata ya zama saiti mai sauƙi na ma'auni.

Sanya abin rufe fuska ko na'urar numfashi a duk lokacin da zai yiwu yayin da kuke aiki da wannan foda-ba shi da haɗari don shaƙa.

Matsar da zarar kun haɗu da daidaiton batir pancake.

3) Sanya ƙirar saka hannun jari a cikin ɗaki don cire duk wani kumfa na iska. Idan ba ku da injin tsabtace ruwa, zaku iya barin shi kawai ya zauna na mintuna 10-20. Kumfa na iska za su haifar da ramuka, wanda zai iya ƙyale karfe ya shiga ciki kuma ya haifar da kayan ado na ƙarshe mai alamar aljihu.

4) Zuba cakuda kayan kwalliyar saka hannun jari a cikin filashin, kewaye da samfurin kakin zuma. Za ku rufe kwatankwacin ku a cikin filasta. Sake tsoma ruwan cakuda don kawar da duk wani kumfa na ƙarshe kafin ya ci gaba.

Kunna wani Layer na famfo a saman saman flask ɗin, ta yadda rabin tef ɗin ya zauna a kan leɓe kuma yana taimakawa ɗaukar filastar daga kumfa.

Bada izinin saka hannun jari ya saita. Bi ainihin umarnin da lokacin bushewa don cakuda filasta kafin ci gaba. Idan an gama, cire tef ɗin kuma goge duk wani filastar da ya wuce kima daga saman ƙirar.

5) Sanya tulun gaba ɗaya a cikin kwanon da aka saita zuwa kusan 1300 F (digiri 600 C). Lura, filasta daban-daban na iya samun yanayin zafi daban-daban. Duk da haka, kada ku kasance a wani abu ƙasa da 1100. Wannan zai taurare ƙirar kuma ya narke da kakin zuma, barin wani ɗaki mara kyau a tsakiyar simintin kayan ado na simintin gyare-gyare.

Wannan na iya ɗaukar har zuwa awanni 12.

Idan kana da kiln lantarki, gwada saita shi don tada zafin jiki a hankali har zuwa 1300. Wannan zai iya taimakawa wajen hana fashewa.

6) Cire flask daga murhu yayin zafi, kuma a duba ƙasan ƙirar don hanawa. Tabbatar cewa kakin zuma mai zafi zai iya fita cikin sauki cikin sauki, kuma babu wani abin da zai hana shi. Idan babu komai a hanya, girgiza flask ɗin a hankali don tabbatar da cewa duk kakin zuma ya fito. Ya kamata a sami wani kududdufi na kakin zuma a cikin tafki na flask ko a ƙasan murhu.

Tabbatar kun sanya safofin hannu masu aminci da tabarau.

3. Zubar da Kayan Ado

1) Sanya karfen da kake so a cikin mazugi mai zubewa, sannan narka shi a cikin wani makera. Za a ƙayyade zafin jiki da lokacin narkewa ta nau'in ƙarfe da kuke amfani da shi. Hakanan zaka iya amfani da tocila da ƙarami don narkar da azurfarka. Wannan nau'in simintin gyare-gyaren hannu ne don ƙaramin aikin samarwa.

2) Yi amfani da nau'in simintin gyare-gyare na kayan ado (Vacuum Pressure Casting Machine) don zub da ƙarfe a cikin ƙirar. Don ƙwararrun kayan adon, za ku buƙaci injin simintin nau'in vacuum tare da iskar gas don kariya. Wannan daidai gwargwado yana rarraba karfe cikin sauri, amma ba shine kawai zaɓin da kuke da shi don yin simintin gyaran kafa ba. Mafi al'ada, mafi sauƙin bayani shine kawai a zub da ƙarfe a hankali a cikin rami da aka bari ta gindin ƙirar.

Kuna iya amfani da sirinji mai ƙayyadaddun ƙarfe don zubar da ƙarfen a cikin ƙirar, ma.

3) Bada karfe ya yi sanyi na tsawon mintuna 5-10, sannan a zuba shi a hankali a cikin ruwan sanyi. Yawan lokacin da yake buƙatar kwantar da hankali yana dogara, ba shakka, akan karfen da aka narke da amfani. Dunk ma da wuri kuma ƙarfe na iya tsage-dunk ya yi latti kuma zai yi wuya a cire duk filastar daga ƙarfe mai taurin.

Nemo lokutan sanyaya don karfen ku kafin ci gaba. Wannan ya ce, idan kun kasance a cikin wani abincin tsami za ku iya jira kawai minti 10 sannan ku zuba a cikin ruwan sanyi.

Ya kamata filastar ta fara narkewa yayin da kuke girgiza shi a kusa da ruwan sanyi.

4) Matsa ƙirar a hankali tare da guduma don kawar da duk wani abin da ya wuce gona da iri da bayyana kayan adon. Ware flask ɗin daga gindin sprue kuma yi amfani da yatsanka ko buroshin haƙori don kawar da duk wani abu na ƙarshe da ya makale a kayan adon.

4. Kammala Kayan Adon Ku

1) Yi amfani da injin niƙa tare da dabaran da aka yanke don yanke duk wani layi na ƙarfe daga sprues. Yanke ɓangarorin ƙarfe na bakin ciki waɗanda kuke buƙatar ƙirƙirar rami don zub da ƙarfe a ciki. Injin na hannu ya kamata ya fi ƙarfin isa.

2) Yi la'akari da wanka na acid ko wanka don share duk wani yanki na ƙarshe na filasta. Tsarin harbe-harbe sau da yawa yakan bar ƙarfe mai laushi da ƙazanta. Kuna iya bincika takamaiman wankin don wasu karafa, wanda zai haifar da haske mai kyau da sauƙin aikin tsaftace yanki daga baya.

3) Kashe duk wani rashin daidaituwa akan kayan adon ta amfani da dabaran buffing karfe. Yi amfani da fayiloli, tufafin enamel, goge-goge, da sauransu don tsaftace yanki har zuwa salon da kuke so. Idan kun shirya kafa dutse, yi bayan kun gama gogewa.