raga 100 – 400 Metal Powder Water Atomizer Machine

Ma'aunin Fasaha

| Model No. | HS-MGA5 | HS-MGA10 | HS-MGA30 | HS-MGA50 | Saukewa: HS-MGA100 |

| Wutar lantarki | 380V 3 matakai, 50/60Hz | ||||

| Tushen wutan lantarki | 15KW | 30KW | 30KW/50KW | 60KW | |

| iya aiki (Au) | 5kg | 10kg | 30kg | 50kg | 100kg |

| Max Temp. | 1600°C/2200°C | ||||

| Lokacin narkewa | 3-5 min. | 5-8 min. | 5-8 min. | 6-10 min. | 15-20 min. |

| Barbashi hatsi (Mesh) | 200#-300#-400# | ||||

| Daidaiton Temp | ±1°C | ||||

| Vacuum Pump | High quality high matakin injin digiri injin famfo | ||||

| Ultrasonic tsarin | High quality Ultrasonic tsarin kula da tsarin | ||||

| Hanyar aiki | Aiki mai maɓalli ɗaya don kammala gabaɗayan tsari, POKA YOKE tsarin mara hankali | ||||

| Tsarin Gudanarwa | Mitsubishi PLC+Manyan-na'ura dubawa na fasaha kula da tsarin | ||||

| Inert gas | Nitrogen / Argon | ||||

| Nau'in sanyaya | Mai sanyin ruwa (Sayar da shi daban) | ||||

| Girma | kusan3575*3500*4160mm | ||||

| Nauyi | kusan2150 kg | kusan3000kg | |||

Atomization pulverizing Hanyar sabon tsari ne da aka haɓaka a cikin masana'antar ƙarfe na foda a cikin 'yan shekarun nan.Yana da abũbuwan amfãni daga cikin sauki tsari, sauki fasaha don Master, abu ba sauki a oxidized, da kuma babban mataki na sarrafa kansa.

1. Takamaiman tsari shine bayan narke (karfe) da kuma tacewa a cikin tanderun shigar da ruwa, ana zubar da ruwan da aka narkar da shi a cikin kwandon adana zafi kuma ya shiga cikin bututun jagora da bututun ƙarfe.A wannan lokacin, ruwan narke yana toshewa ta hanyar ruwa mai matsananciyar matsa lamba (ko iskar gas) The atomized da atomized karfe foda yana da ƙarfi kuma ya zauna a cikin hasumiya na atomization, sa'an nan kuma ya fada cikin tanki na tattara foda don tarawa da rabuwa.Ana amfani da shi sosai a fagen ƙarancin ƙarfe wanda ba na ƙarfe ba kamar foda baƙin ƙarfe atomized, foda na jan karfe, foda bakin karfe da gami foda.Fasahar masana'antu na cikakkun kayan aikin foda na ƙarfe, kayan aikin foda na jan karfe, kayan aikin foda na azurfa da kayan aikin foda na allo yana ƙara girma.

2. Amfani da ka'idar ruwa atomization pulverizing kayan aiki, ruwa atomization pulverizing kayan aiki ne na'urar da aka tsara don saduwa da samar da ruwa atomization pulverizing tsari a karkashin yanayi yanayi, kuma shi ne mai masana'antu samar da taro.Ka'idar aiki na na'urar atomization na ruwa tana nufin narkewar ƙarfe ko ƙarfe a ƙarƙashin yanayin yanayi.A karkashin yanayin kariyar iskar gas, ruwan karfe yana gudana ta cikin tundish na thermal insulation da bututun karkatar da ruwa, kuma ruwan matsananciyar matsananciyar matsananciyar ruwa yana gudana ta cikin bututun ƙarfe.A karfe ruwa ne atomized da kuma karye a cikin wani babban adadin lafiya karfe droplets, da kyau droplets samar da sub-spherical ko rashin daidaituwa barbashi a karkashin hade mataki na surface tashin hankali da kuma m sanyaya ruwa a lokacin jirgin don cimma manufar milling.

3. Ruwa atomization pulverizing kayan aiki yana da wadannan halaye: 1. Yana iya shirya mafi yawan karfe da gami foda, da kuma samar da kudin ne low.2. Subspherical foda ko foda mara kyau za a iya shirya.3. Saboda saurin ƙarfafawa kuma babu rarrabuwa, ana iya shirya foda na musamman na musamman.4. Ta hanyar daidaita tsarin da ya dace, girman ƙwayar foda zai iya isa iyakar da ake bukata.

4. Tsarin ruwa atomization pulverizing kayan aiki Tsarin ruwa atomizing pulverizing kayan aiki kunshi wadannan sassa: smelting, tundish tsarin, atomization tsarin, inert gas kariya tsarin, matsananci-high matsa lamba ruwa tsarin, foda tarin, dehydration da bushewa tsarin. tsarin nunawa, tsarin ruwa mai sanyaya, tsarin kula da PLC, tsarin dandamali, da dai sauransu. 1. Narkewa da tsarin tundish: A gaskiya ma, shi ne matsakaicin mita shigar da wutar lantarki, wanda ya ƙunshi: harsashi, induction nada, na'urar auna zafin jiki, murƙushe tanderu. na'ura, tundish da sauran sassa: harsashi tsari ne na firam, wanda shi ne carbon An yi shi da ƙarfe da bakin karfe, ana sanya coil induction a tsakiya, kuma ana sanya crucible a cikin coil induction, wanda za'a iya narke a zuba.An shigar da tundish akan tsarin bututun ƙarfe, ana amfani da shi don adana narkakken ruwa na ƙarfe, kuma yana da aikin adana zafi.Ya fi ƙanƙara fiye da ƙwanƙwasa na tsarin narkewa.Tanderun da ke riƙe da tundish yana da nasa tsarin dumama da tsarin auna zafin jiki.Tsarin dumama wutar lantarki yana da hanyoyi guda biyu: juriya dumama da induction dumama.Juriya dumama zafin jiki iya kullum isa 1000 ℃, da shigar da dumama zazzabi iya isa 1200 ℃ ko mafi girma, amma crucible abu ya kamata a zaba a hankali.2. Atomization tsarin: Atomization tsarin kunshi nozzles, high-matsi ruwa bututu, bawuloli, da dai sauransu. na foda, wani adadin iskar gas yawanci ana shigar da shi cikin hasumiya atomization don kariyar yanayi.4. Tsarin ruwa mai matsananciyar matsa lamba: Wannan tsarin na'ura ce da ke samar da ruwa mai ƙarfi don atomizing nozzles.Ya ƙunshi famfunan ruwa masu ƙarfi, tankunan ruwa, bawuloli, tudu masu matsa lamba da kuma bas.5. Tsarin kwantar da hankali: Duk na'urar tana sanye da ruwan sanyi, kuma tsarin sanyaya yana da mahimmanci.Za a nuna yanayin zafin ruwan sanyi akan kayan aiki na biyu don tabbatar da amincin aikin na'urar.6. Tsarin sarrafawa: Tsarin sarrafawa shine cibiyar kula da aiki na na'urar.Dukkan ayyuka da bayanan da ke da alaƙa ana watsa su zuwa PLC na tsarin, kuma ana sarrafa sakamakon, adanawa da nunawa ta hanyar ayyuka.

R & D da kuma samar da ƙwararrun kayan aiki don shirye-shiryen sabon kayan foda, samar da ƙwararrun jerin mafita don samar da sababbin kayan foda na ci gaba, fasahar shirye-shiryen foda mai siffar zobe tare da haƙƙin mallaka na fasaha mai zaman kanta / zagaye da fasaha na shirye-shiryen foda / tsiri foda shirye-shiryen fasaha / flake fasahar shirye-shiryen foda, kazalika da fasaha na shirye-shiryen foda na ultrafine / nano, fasaha mai tsabta mai tsabta mai tsabta.

Tsari Na Yin Foda Karfe Ta Ruwan Atomization Kayan Aikin Juya

Tsarin yin foda na ƙarfe ta hanyar ruwa atomization pulverizing kayan aiki yana da dogon tarihi.A zamanin d ¯ a, mutane suna zuba narkakkar ƙarfe a cikin ruwa don ya fashe cikin ɓangarorin ƙarfe masu kyau, waɗanda ake amfani da su azaman ɗanyen ƙarfe don yin ƙarfe;har ya zuwa yanzu, akwai mutanen da ke zuba dalma dalma kai tsaye a cikin ruwa don yin kwalwar dalma..Yin amfani da hanyar atomization na ruwa don yin foda mara nauyi, ƙa'idar tsari iri ɗaya ce da ruwan da aka ambata a sama mai fashe ruwan ƙarfe, amma an inganta ingantaccen aikin ɗigon ruwa.

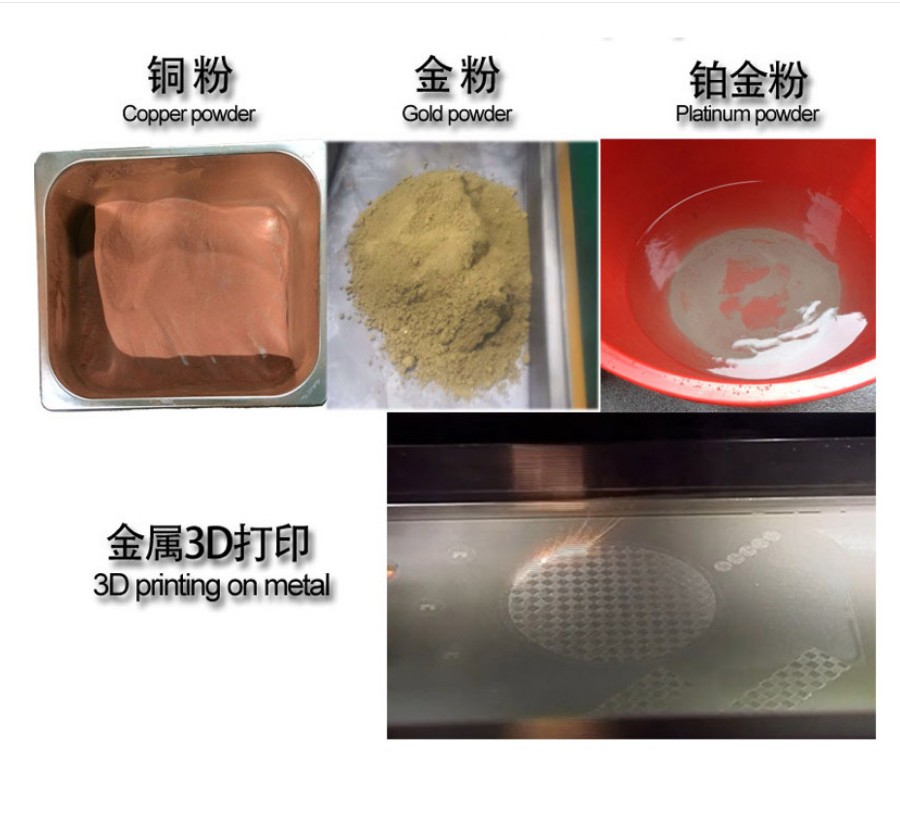

The ruwa atomization pulverizing kayan aiki sa m gami foda.Da farko, an narkar da gwal ɗin gwal a cikin tanderun.Ruwan zinare da aka narke dole ne a yi zafi da shi da kusan digiri 50, sannan a zuba a cikin tundish.Fara famfo mai matsa lamba na ruwa kafin a yi allurar ruwan gwal, kuma bari babban na'urar atomization na ruwa ta fara aikin.Ruwan zinare a cikin tundish yana wucewa ta cikin katako kuma ya shiga cikin atomizer ta bututun ruwa mai zube a kasan tundish.Atomizer shine mabuɗin kayan aiki don yin ƙaƙƙarfan foda na gwal ta hanyar hazo mai ƙarfi.Ingancin na'urar atomizer yana da alaƙa da murkushe ingancin ƙarfe foda.Karkashin aikin ruwa mai matsa lamba daga atomizer, ruwan gwal yana ci gaba da karyewa zuwa ɗigo masu kyau, waɗanda ke faɗowa cikin ruwa mai sanyaya a cikin na'urar, kuma ruwan yana daɗa ƙarfi cikin sauri ya zama foda.A cikin tsarin gargajiya na yin foda na ƙarfe ta hanyar atomization na ruwa mai ƙarfi, ana iya tattara foda na karfe gabaɗaya, amma akwai yanayin cewa ɗan ƙaramin foda na ƙarfe ya ɓace tare da ruwan atomizing.A cikin aiwatar da yin alloy foda ta hanyar atomization na ruwa mai ƙarfi, samfurin atomized yana mai da hankali a cikin na'urar atomization, bayan hazo, tacewa, (idan ya cancanta, ana iya bushe shi, yawanci kai tsaye aika zuwa tsari na gaba.), Don samun lafiya Alloy foda, babu asarar gami foda a cikin dukan tsari.

Cikakken saitin na'urar atomization na ruwa Kayan aiki don yin gami foda ya ƙunshi sassa masu zuwa:

Bangaren narkewa:Za a iya zaɓar tanderun ƙarfe na ƙarfe na tsaka-tsaki ko babban tanderun ƙarfe na ƙarfe.An ƙaddara ƙarfin wutar lantarki bisa ga girman aiki na foda na karfe, kuma za a iya zaɓar tanderun kilo 50 ko tanderun kilo 20.

Bangaren atomization:Kayan aiki a cikin wannan bangare ba kayan aiki ba ne, wanda ya kamata a tsara shi kuma a tsara shi bisa ga yanayin wurin mai sana'a.Akwai mafi yawan tundishes: lokacin da aka samar da tundish a cikin hunturu, yana buƙatar a rigaya;Atomizer: Atomizer zai fito daga babban matsi Ruwan famfo mai ƙarfi yana tasiri ruwan gwal daga tundish a ƙayyadaddun gudu da kusurwa, yana karya shi cikin ɗigon ƙarfe.Karkashin matsa lamba na famfo guda ɗaya, adadin foda mai kyau na ƙarfe bayan atomization yana da alaƙa da ingancin atomization na atomizer;Silinda atomization: shine wurin da ake karkatar da foda, a niƙa, sanyaya da tattara.Don hana ultra-fine alloy foda a cikin foda da aka samu daga rasawa da ruwa, ya kamata a bar shi na wani lokaci bayan atomization, sa'an nan kuma sanya shi a cikin akwatin tattara foda.

Bangaren sarrafawa:Akwatin tattara foda: ana amfani da shi don tattara foda mai atomized da raba da cire ruwa mai yawa;bushewa tanderu: bushe da rigar gami foda da ruwa;Injin nuni: sieve da gami foda, Za a iya sake narkar da foda mai ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwan da za a iya narkar da su a matsayin kayan dawowa.

Vacuum Air Atomization Technology Pulverizing Technology Da Aikace-aikacensa

The foda tattalin injin iska atomization yana da abũbuwan amfãni daga high tsarki, low oxygen abun ciki da lafiya foda size.Bayan shekaru na ci gaba da haɓakawa da haɓakawa, fasahar atomization na iska ta haɓaka a cikin babban hanyar samar da ƙarfe mai ƙarfi da foda mai ƙarfi, kuma ya zama babban abin da ke tallafawa da haɓaka binciken sabbin kayan aiki da haɓaka sabbin fasahohi.Editan ya gabatar da ka'ida, tsari da kayan aikin niƙa foda na atomization na iska, kuma yayi nazarin nau'ikan da amfani da foda da aka shirya ta hanyar atomization na iska.

Hanyar atomization hanya ce ta shirye-shiryen foda wanda ruwa mai saurin tafiya (atomizing matsakaici) ya yi tasiri ko in ba haka ba ya karya karfe ko ruwan gawa zuwa ɗigo mai kyau, wanda sai a tatse su zama foda mai ƙarfi.A atomized foda barbashi ba kawai suna da ainihin kama kama sinadaran abun da ke ciki a matsayin ba narkakkar gami, amma kuma saboda m solidification refines da crystalline tsarin da gusar da macrosegregation na biyu lokaci.Matsakaicin atomization da aka saba amfani dashi shine ruwa ko ultrasonic, wanda ake kira ruwa atomization da gas atomization daidai da haka.The karfe foda shirya ta ruwa atomization da high yawan amfanin ƙasa da kuma tattalin arziki yawan amfanin ƙasa, da kuma sanyaya kudi ne da sauri, amma powders da high oxygen abun ciki da kuma rashin daidaituwa ilimin halittar jiki, yawanci flakes.The foda tattalin ultrasonic atomization fasaha yana da kananan barbashi size, high sphericity da low oxygen abun ciki, kuma ya zama babban hanya domin samar da high-yi mai siffar zobe karfe da gami powders.

Vacuum smelting high-matsi iskar gas atomization pulverizing fasaha hade high-vacuum fasaha, high-zazzabi fasahar smelting, high-matsi da high-gudun gas fasahar, kuma an samar don saduwa da bukatun na foda karafa , musamman ga samar da high- Alloys masu inganci dauke da abubuwa masu aiki foda.Ultrasonic / Gas atomization pulverizing fasaha ne sabon m solidification fasaha.Saboda yawan kwantar da hankali, foda yana da halaye na gyaran ƙwayar hatsi, abun da ke ciki na uniform da babban m solubility.

Bugu da ƙari ga fa'idodin da ke sama, foda na ƙarfe da aka samar ta hanyar vacuum na narkewar iskar gas mai ƙarfi yana da halaye uku masu zuwa: foda mai tsabta, ƙananan abun ciki na oxygen;yawan amfanin ƙasa mai kyau foda;high bayyanar sphericity.Kayan tsari ko kayan aiki da aka yi daga wannan foda suna da fa'ida da yawa akan kayan al'ada dangane da kaddarorin jiki da sinadarai.Abubuwan da aka ƙera sun haɗa da foda superalloy, thermal spray alloy foda, jan alloy foda da bakin karfe.

1 Vacuum iska atomization foda milling tsari da kayan aiki

1.1 Vacuum iska atomization foda milling tsari

The injin atomization pulverizing hanya ne wani sabon irin tsari ci gaba a karfe foda masana'antu masana'antu a cikin 'yan shekarun nan.Yana da abũbuwan amfãni daga ba sauki hadawan abu da iskar shaka na kayan, m quenching na karfe foda, da kuma babban mataki na aiki da kai.Takamammen tsari shine bayan an narkar da gami (karfe) kuma an tace shi a cikin tanderun induction, ana zuba ruwan narkakken karfe a cikin slump na thermal insulation, sannan ya shiga cikin bututun jagora da bututun ƙarfe, kuma ruwan narke yana atomized da babban- matsa lamba gas kwarara.Ƙarfe ɗin foda mai atom ɗin yana ƙarfafa kuma ya zauna a cikin hasumiya na atomization, kuma ya faɗi cikin tankin tattara foda.

Atomizing kayan aiki, atomizing ultrasonic da karfe ruwa kwarara su ne uku na asali al'amurran da gas atomization tsari.A cikin atomization kayan aiki, da allura atomizing ultrasonic accelerates da hulda tare da allura karfe ruwa kwarara zuwa samar da wani kwarara filin.A cikin wannan filin kwararowar, gangaren karfen ya karye, sanyaya kuma yana da ƙarfi, ta haka ne ake samun foda tare da wasu halaye.The sigogi na atomization kayan aiki sun hada da bututun ƙarfe tsarin, catheter tsarin, catheter matsayi, da dai sauransu, atomization gas da tsarin sigogi sun hada da ultrasonic Properties, iska shigar da matsa lamba, iska gudu, da dai sauransu, da karfe ruwa kwarara da tsarin sigogi sun hada da karfe ruwa ya kwarara. Properties, superheat, ruwa ya kwarara diamita, da dai sauransu Ultrasonic atomization cimma manufar daidaitawa foda barbashi size, barbashi size rarraba da microstructure ta daidaitawa daban-daban sigogi da daidaitawa.

1.2 Vacuum iska atomization pulverizing kayan aiki

Na'ura mai juzu'i na vacuum atomization na yanzu sun haɗa da kayan waje da kayan gida.Kayan aikin da aka samar a kasashen waje yana da babban kwanciyar hankali da madaidaicin kulawa, amma farashin kayan aiki yana da yawa, kuma kulawa da gyarawa yana da yawa.Kudin kayan aikin gida yana da ƙasa, farashin kulawa yana da ƙasa, kuma kulawa ya dace.Koyaya, masana'antun kayan aikin cikin gida gabaɗaya ba su ƙware ainihin fasahar kayan aiki kamar atomizing nozzles da tsarin atomization.A halin yanzu, cibiyoyin bincike na ƙasashen waje masu dacewa da masana'antun samarwa suna kiyaye fasahar a asirce sosai, kuma ƙayyadaddun sigogin tsarin masana'antu da masana'antu ba za a iya samu daga wallafe-wallafen da suka dace ba.Wannan ya sa amfanin foda mai inganci ya yi ƙasa da ƙasa don ya zama mai tattalin arziki, wanda kuma shine babban dalilin da ya sa ƙasata ba ta iya samar da foda mai inganci a masana'antu duk da cewa akwai da yawa aerosol samar da foda da kuma binciken kimiyya.

Tsarin ultrasonic atomization pulverizing na'urar ya ƙunshi sassa masu zuwa: matsakaiciyar mitar induction narkewa tanderu, riƙe tanderu, tsarin atomization, tankin atomization, tsarin tarin ƙura, tsarin samar da ultrasonic, tsarin sanyaya ruwa, tsarin sarrafawa, da sauransu.

A halin yanzu, bincike daban-daban kan iskar iska ya fi mayar da hankali ne kan bangarori biyu.A gefe guda, ana nazarin sigogi na tsarin bututun ƙarfe da halayen jigilar jet.Manufar ita ce don samun dangantaka tsakanin filin iska da tsarin bututun ƙarfe, don haka ultrasonic ya kai saurin gudu a bututun bututun ruwa yayin da ƙarancin ƙuri'a na ultrasonic kaɗan ne, kuma yana ba da tushen ka'idar ƙira da sarrafa bututun ƙarfe.A gefe guda, an yi nazarin dangantaka tsakanin sigogin tsarin atomization da kaddarorin foda.Yana nufin yin nazarin sakamako na atomization tsarin sigogi a kan foda Properties da atomization yadda ya dace a kan wani bututun ƙarfe-takamaiman tushe don inganta da kuma shiryar da foda samar.A cikin wata kalma, inganta yawan aiki na lafiya foda da rage yawan amfani da iskar gas yana jagorantar jagorancin ci gaban fasahar atomization na ultrasonic.

1.2.1 Daban-daban iri nozzles ga ultrasonic atomization

The atomizing gas yana ƙara gudu da kuzari ta cikin bututun ƙarfe, ta yadda yadda ya kamata karya ruwa karfe da shirya foda wanda ya dace da bukatun.The bututun ƙarfe iko da kwarara da kwarara juna na atomized matsakaici, da kuma taka muhimmiyar rawa a matakin atomization yadda ya dace da kwanciyar hankali na atomization tsari, kuma shi ne key fasaha na ultrasonic atomization.A farkon tsarin sarrafa iskar gas, ana amfani da tsarin bututun mai kyauta gabaɗaya.Wannan bututun ƙarfe yana da sauƙi a cikin ƙira, ba sauƙin toshewa ba, kuma tsarin sarrafawa yana da sauƙi mai sauƙi, amma ƙimar atomization ɗinsa ba ta da girma, kuma ya dace kawai don samar da foda tare da girman barbashi na 50-300 μm.Domin inganta aikin atomization, an ƙirƙiri ƙuntatawa nozzles ko kuma haɗe-haɗe atomizing nozzles daga baya.Ƙunƙarar ƙanƙara ko ƙuntataccen bututun iskar gas yana rage nisan jirgin gas kuma yana rage asarar makamashin kuzari a cikin tsarin tafiyar da iskar gas, ta haka yana ƙara saurin gudu da yawan iskar gas ɗin da ke mu'amala da ƙarfe, da ƙara yawan amfanin ƙasa mai kyau.

1.2.1.1 Matsakaicin Ramin bututun ƙarfe

Babban matsa lamba ultrasonic yana shiga cikin bututun ƙarfe tangtially.Sa'an nan kuma a fitar da shi da sauri don samar da vortex

Don haɓaka bugu na 3D, Sin na buƙatar Gina Sarkar Ƙirƙirar Ƙirƙirar kanta da Sarkar masana'antu.

A cikin shekaru biyu da suka gabata, ci gaban masana'antun masana'antar ƙari ya tashi zuwa matakin dabarun ƙasa.An fitar da takardu kamar "Made in China 2025" da "Tsarin Ayyukan Ci Gaban Masana'antu na Ƙasa (2015-2016)".A ƙari masana'antu masana'antu ya ci gaba da sauri.Muhimmancin masana'antun da suka dogara da fasaha suna haɓaka.Duk da haka, saboda masana'antun masana'antu suna cikin farkon matakan ci gaba, har yanzu yana nuna halaye na ƙananan sikelin.Masana sun yarda cewa kayayyakin da ake shigowa da su daga kasashen waje yanzu suna "kai hari" kasuwannin kasar Sin.Ɗaukar kayan aikin buga ƙarfe a matsayin misali, ƙasashen waje suna aiwatar da haɗe-haɗen tallace-tallace na kayan, software, kayan aiki da matakai.Dole ne ƙasata ta hanzarta bincike da haɓaka manyan fasahohi da fasahohin asali, da ƙirƙirar sarkar ƙirƙira da sarkar masana'antu.

Hasashen kasuwa yana da kyau

A cewar wani rahoto na McKinsey, masana'antar ƙari ya zama matsayi na tara a cikin fasahohi 12 da ke da tasiri ga rayuwar ɗan adam, gabanin sabbin kayayyaki da iskar gas, kuma ana hasashen cewa nan da shekara ta 2030 masana'antar ƙari za ta kai girman kasuwar kusan dala tiriliyan 1.A cikin 2015, rahoton ya ciyar da wannan tsari gaba, yana mai cewa nan da shekarar 2020, wato shekaru uku bayan haka, girman kasuwar hada-hadar kayan masarufi na iya kaiwa dalar Amurka biliyan 550.Rahoton McKinsey ba shi da ban sha'awa ba.

Lu Bingheng, masani na Kwalejin Injiniya ta kasar Sin kuma darektan Cibiyar kere-kere ta kasa da kasa, ya yi amfani da "hudu da rabi" wajen takaita makomar kasuwar hada-hadar kayayyaki.

An tsara fiye da rabin ƙimar samfurin a nan gaba;

Fiye da rabin samar da samfur an keɓance;

Fiye da rabin samfuran samarwa suna cunkoso;

Fiye da rabin sabbin abubuwa masu yin su ne ke yin su.

Ƙarfafa masana'antu fasaha ce mai rushewa wanda ke jagorantar ci gaban masana'antar masana'antu.Fasaha ce da ta dace don tallafawa ƙira ƙira, samarwa da aka keɓance, ƙirƙira ƙira da masana'antar cunkoson jama'a."Mahimmiyar mahimmanci, masana'antar ƙari wata fasaha ce da ba kasafai ake yin aiki da ita da duniya ba a cikin ƙasata. A halin yanzu, binciken da Sin ta yi kan bugu na 3D ya kasance kan gaba a duniya."

Lu Bingheng ya ce, a halin yanzu, bisa dogaro da manyan na'urorin buga karafa na 3D da kasarta da kanta ta kera, kasar Sin tana kan matsayin kasa da kasa wajen yin amfani da manyan sassa na jiragen sama masu daukar nauyi, kuma tana aiki a matsayin tawagar agajin farko a cikin bincike da haɓaka jiragen soja da manyan jiragen sama.Haka kuma, an yi amfani da manyan sassa na tsarin titanium a cikin bincike da haɓaka kayan saukar jirgin sama da C919.

Dangane da aikace-aikace, kasata tana da karfin kayan aikin masana'antu a matsayi na hudu a duniya, amma kayan aikin da aka yi ciniki don buga karafa har yanzu suna da rauni sosai, kuma galibi sun dogara ne kan shigo da kaya.Duk da haka, a cewar jami'in ilimi Lu Bingheng, babban burin kasar Sin na kera kayan karawa, shi ne cimma matsayi na biyu mafi girma a duniya da aka girka, da kuma samar da kayan aiki mafi girma na uku a duniya cikin shekaru 5;kuma mafi girma na biyu mafi girma a duniya shigar iya aiki, ainihin na'urori da fasaha na asali, da tallace-tallacen kayan aiki a cikin shekaru 10.Cimma "Made in China 2025" a 2035.

Ci gaban masana'antu yana haɓaka

Bayanai sun nuna cewa matsakaicin girman girman kasuwa na masana'antar ƙari a cikin shekaru uku da suka gabata.Yawan ci gaban wannan masana'antu a kasar Sin ya zarce na duniya.

Alamar alama: yawanci yana nufin abin da ake yi don tsara wasu ƙa'idodi na yau da kullun a cikin harabar

Alamomi, irin su: alamun furanni da ciyawa, babu alamun hawan hawan, da dai sauransu. Ragewa, amma a cikin filin sabis, yawan ci gaba yana da sauri sosai saboda inganta ƙwarewar abokin ciniki."Musamman a cikin sarrafa kayayyaki da masana'antu, yawan odar mu ya ninka."Cibiyar Buga masana'antu ta Weinan 3D a lardin Shaanxi, tare da tallafin ƙaramar hukuma, ya canza fa'idar fasahar bugun 3D zuwa fa'idodin masana'antu tare da haɓaka haɓakawa da sauya masana'antu na gargajiya.Halin al'ada na fahimtar ci gaban tari.

Mayar da hankali a kan masana'antu shiryawa ra'ayi na "3D bugu +", shi ne ba kawai don bunkasa 3D bugu masana'antu, amma don mayar da hankali a kan samar da 3D bugu kayan aiki, da bincike da ci gaba da kuma samar da 3D bugu karfe kayan, da kuma horo. na 3D bugu na aikace-aikace-daidaitacce baiwa.Kafe a cikin manyan masana'antu na cikin gida, mai da hankali kan aiwatar da aikace-aikacen nunin 3D bugu na masana'antu, haɓaka haɓaka bugu na 3D tare da masana'antun gargajiya, da aiwatar da jerin bugu na 3D + samfuran masana'antu kamar 3D bugu + jirgin sama, mota, al'adu da ƙirƙira, simintin gyare-gyare, ilimi, da dai sauransu, tare da taimakon bugu na 3D Fa'idodin fasahar bugu, warware matsalolin fasaha da wuraren zafi na masana'antun gargajiya, canza da haɓaka masana'antar gargajiya, da gabatarwa da haɓaka nau'ikan masana'antar fasaha daban-daban kanana da matsakaitan masana'antu. .

Bisa kididdigar da aka yi, ya zuwa watan Mayu 2017, yawan kamfanoni ya kai 61, kuma fiye da ayyuka 50 irin su 3D molds, 3D, 3D masana'antu inji, 3D kayan, 3D ayyukan al'adu da kere-kere, da ake sa ran za a ajiye. a aiwatar.Ana sa ran nan da karshen shekarar, adadin kamfanonin zai zarce 100.

Kunna sarkar bidi'a da sarkar masana'antu

Duk da haɓakar haɓakar masana'antar masana'anta ta ƙasata, masana'antar har yanzu tana kan matakin farko na ci gaba kuma har yanzu tana da halayen ƙarancin sikelin.Duk da haka, rashin balagaggen fasaha, tsadar aikace-aikace, da ƙarancin aikace-aikacen aikace-aikacen sun sa masana'antar gaba ɗaya ta kasance cikin yanayin "kanana, warwatse da rauni".Duk da cewa kamfanoni da dama sun fara taka kafa a fannin kera kayan kara, amma akwai karancin manyan kamfanonin Driven, ma'aunin masana'antar kadan ne.Masanin ilimin kimiyya Lu Bingheng ya bayyana cewa, a matsayin daya daga cikin muhimman fasahohin juyin juya halin masana'antu a nan gaba, ya kamata a kara habaka ci gaban masana'antu, saboda fasahar buga 3D tana cikin wani yanayi na fasa bugu da fasahohi, da lokacin fara masana'antu, kuma lokaci na "ciwon kai" na kamfanoni.Babban buƙatun kasuwa na iya haifar da haɓaka fasahar fasaha da filin kayan aiki, wanda dole ne a kiyaye shi da cikakken amfani da shi don jagora da tallafawa masana'antar kayan aikin mu.

Yanzu kayan aikin da aka shigo da su suna "kai hari" kasuwar Sinawa.Don kayan aikin bugu na ƙarfe, ƙasashen waje suna aiwatar da tallace-tallace da yawa na kayan, software, kayan aiki, da matakai.Dole ne kamfanonin kasar Sin su samar da muhimman fasahohi da fasahohin asali don samar da nasu sabbin fasahohin da masana'antu.

Masu binciken masana'antu sun ce ga masana'antar buga 3D ta cikin gida a halin yanzu, matakin bincike da haɓaka fasahar gaba ɗaya an yi amfani da su ga masana'antar, kuma yawancin nasarorin fasaha suna cikin matakin dakin gwaje-gwaje ne kawai.Babban dalilan wannan matsala sune: na farko, saboda ma'auni daban-daban, samun dama ga cancantar ba cikakke ba ne, kuma akwai shingen da ba a iya gani ba na shiga;Na biyu, cibiyoyin bincike na kimiyya da masana'antu ba su da tasiri mai ma'ana, suna cikin yanayin fada su kadai, ba su da 'yancin yin magana a cikin shawarwarin masana'antu, kuma suna cikin wahala;Sabuwar masana'antar ba a fahimta sosai ba, kuma akwai rikice-rikice ko rashin fahimta, wanda ke haifar da jinkirin aikace-aikacen fasaha.

Haɓaka Haɓaka Na Atomization Pulverizing Kayan Aiki Nan gaba

Har yanzu akwai nakasu da yawa a cikin fahimtar fasahar bugu na 3D a dukkan fannonin masana'antun kasar Sin.Yin la'akari da halin da ake ciki na ci gaba, ya zuwa yanzu 3D bugu bai samu balagagge masana'antu ba, daga kayan aiki zuwa samfurori zuwa ayyuka har yanzu a cikin mataki na "ci gaba".Duk da haka, daga gwamnati har zuwa kamfanoni a kasar Sin, ana ganin ci gaban fasahar buga fasahohin 3D gaba daya, kuma gwamnati da al'umma gaba daya sun mai da hankali kan tasirin da fasahar buga karfen atomization na 3D a nan gaba zai haifar da fasahohin samar da kayayyaki da tattalin arzikin kasata. da kuma masana'antu model.

Dangane da bayanan binciken, a halin yanzu, buƙatun ƙasata na fasahar bugu na 3D ba ta ta'allaka ne kan kayan aiki ba, amma tana nunawa a cikin nau'ikan bugu na 3D iri-iri da kuma buƙatar sabis na sarrafa hukuma.Abokan ciniki na masana'antu sune babban karfi wajen siyan kayan bugawa na 3D a cikin ƙasata.Kayan aikin da suke saya ana amfani da su ne a fannin jiragen sama, sararin samaniya, kayayyakin lantarki, sufuri, ƙira, ƙirƙira al'adu da sauran masana'antu.A halin yanzu, ikon shigar da na'urorin buga na'urorin 3D a cikin kamfanonin kasar Sin ya kai kusan 500, kuma yawan karuwar da ake samu a shekara ya kai kusan kashi 60%.Duk da haka, girman kasuwar yanzu kusan yuan miliyan 100 ne kawai a kowace shekara.Bukatar R&D da samar da kayan bugu na 3D ya kai kusan yuan biliyan 1 a kowace shekara.Tare da haɓakawa da ci gaban fasahar kayan aiki, sikelin zai yi girma cikin sauri.A lokaci guda, 3D bugu da alaka da sarrafawa ayyuka ne Popular, da kuma da yawa jamiái 3D bugu Kamfanin kayan aiki ne sosai balagagge a cikin Laser sintering tsari da kayan aiki aikace-aikace, kuma zai iya samar da waje aiki ayyuka.Tun da farashin kayan aiki guda gabaɗaya ya haura yuan miliyan 5, karɓuwar kasuwa ba ta da yawa, amma sabis ɗin sarrafa hukumar ya shahara sosai.

Yawancin kayan da aka yi amfani da su a cikin na'urorin bugun ƙarfe na atomization na 3D na ƙasata ana samar da su kai tsaye daga masana'antun kera samfuri masu sauri, kuma ba a aiwatar da samar da kayan gabaɗaya na ɓangare na uku ba, wanda ke haifar da tsadar kayayyaki.A lokaci guda, babu wani bincike kan shirye-shiryen foda da aka keɓe don bugu na 3D a kasar Sin, kuma akwai ƙaƙƙarfan buƙatu akan rarraba girman ƙwayar cuta da abun ciki na oxygen.Wasu raka'a suna amfani da foda na yau da kullun maimakon, wanda ke da rashin amfani da yawa.

Haɓakawa da samar da ƙarin kayan aiki iri-iri shine mabuɗin ci gaban fasaha.Magance matsalolin aiki da tsadar kayayyaki zai fi inganta haɓaka fasahar yin samfuri cikin sauri a kasar Sin.A halin yanzu, galibin kayayyakin da ake amfani da su wajen buga fasahar 3D na kasata na bukatar a shigo da su daga kasashen waje, ko kuma masana’antun da ke kera kayan aikin sun zuba kudi da yawa don bunkasa su, wadanda suke da tsada, wanda hakan ya haifar da tsadar kayayyakin da ake samarwa, yayin da ake samun karuwar farashin kayayyaki. kayan gida da ake amfani da su a cikin wannan injin suna da ƙarancin ƙarfi da daidaito..Ƙaddamar da kayan bugawa na 3D yana da mahimmanci.

Titanium da titanium gami foda ko nickel-tushen da kuma cobalt tushen superalloy powders tare da low oxygen abun ciki, lafiya barbashi size da high sphericity ake bukata.The foda barbashi size ne yafi -500 raga, da oxygen abun ciki ya zama ƙasa da 0.1%, da barbashi size ne uniform A halin yanzu, high-karshen gami foda da masana'antu kayan aiki har yanzu yafi dogara a kan shigo da.A kasashen waje, ana hada danyen kaya da kayan aiki da yawa ana sayar da su don samun riba mai yawa.Ɗaukar foda mai tushen nickel a matsayin misali, farashin albarkatun ƙasa ya kai yuan 200/kg, farashin kayayyakin gida gabaɗaya yuan 300-400 ne, kuma farashin foda da ake shigo da shi sau da yawa ya fi yuan 800/kg.

Misali, tasiri da daidaitawa na abun da ke cikin foda, haɗawa da kaddarorin jiki akan abubuwan da ke da alaƙa na 3D bugu na ƙarfe atomization foda milling kayan aiki.Saboda haka, a cikin ra'ayi na amfani da bukatun da low oxygen abun ciki da lafiya barbashi size foda, shi ne har yanzu wajibi ne don gudanar da wani bincike aikin kamar abun da ke ciki zane na titanium da titanium gami foda, gas atomization foda milling fasahar na lafiya barbashi size foda, da kuma. tasirin halayen foda akan aikin samfur.Saboda ƙayyadaddun fasahar niƙa a kasar Sin, yana da wuya a shirya foda mai kyau a halin yanzu, yawan foda yana da ƙasa, kuma abun ciki na oxygen da sauran ƙazanta yana da yawa.A yayin aiwatar da aikin, yanayin narkewar foda yana da haɗari ga rashin daidaituwa, yana haifar da babban abun ciki na haɗaɗɗun oxide da samfuran ƙima a cikin samfurin.Matsalolin da ke tattare da foda na gida suna cikin ingancin samfurin da kwanciyar hankali, ciki har da: ① kwanciyar hankali na abubuwan foda (yawan haɓakawa, daidaito na kayan aiki);② foda jiki Kwanciyar aiki (rarrabuwar girman barbashi, foda ilimin halittar jiki, fluidity, sako-sako da rabo, da dai sauransu);③ matsala na yawan amfanin ƙasa (ƙananan yawan amfanin ƙasa na foda a cikin kunkuntar girman girman sashi), da sauransu.

Nuni samfurin

-21.jpg)

-11.jpg)

-21.jpg)