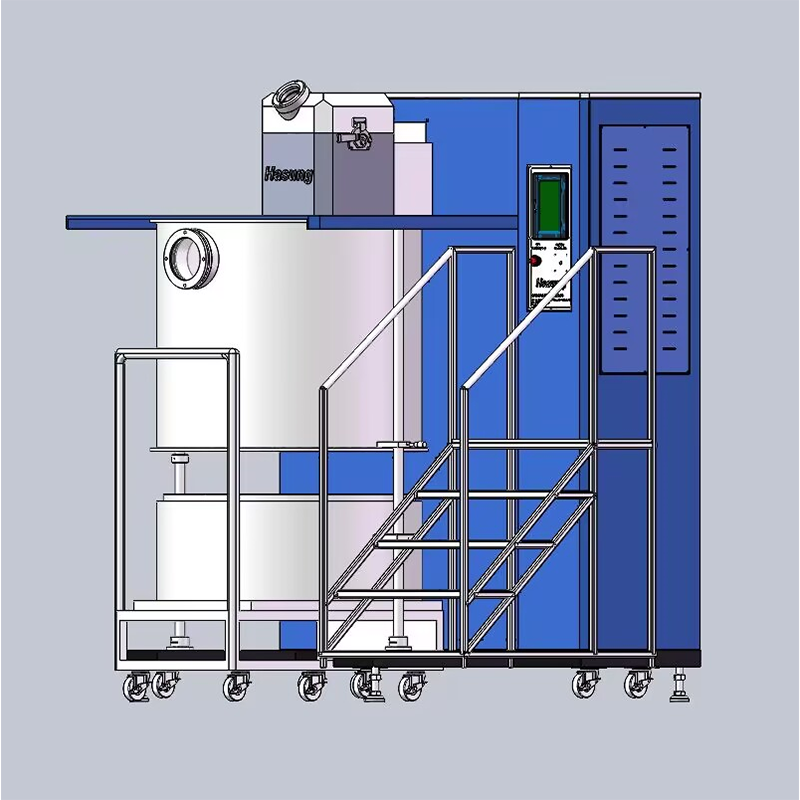

Karfe Powder Water Atomizer Don Kyawun Karfe Platinum Palladium Karfe

Sigar Fasaha

| Model No. | HS-MI4 | HS-MI10 | HS-MI20 |

| Wutar lantarki | 380V 3 matakai, 50/60Hz | ||

| Tushen wutan lantarki | 15KW | 25KW | 40KW |

| Max Temp. | 2100°C | ||

| Lokacin narkewa | 3-5 Minti. | 5-8 Minti. | 5-8 Minti. |

| Ciwon Hatsi | 80#-200#-400#-500# | ||

| Daidaiton Temp | ±1°C | ||

| Iyawa (Pt) | 4kg | 10kg | 30kg |

| Vacuum Pump | (na zaɓi) | ||

| Aikace-aikace | Zinariya, azurfa, jan karfe, gami; Platinum (Na zaɓi) | ||

| Hanyar aiki | Aiki mai maɓalli ɗaya don kammala gabaɗayan tsari, POKA YOKE tsarin mara wawa | ||

| Tsarin Gudanarwa | Taiwan Weinview + Siemens PLC tsarin sarrafa hankali | ||

| Garkuwar Gas | Nitrogen / Argon | ||

| Nau'in sanyaya | Mai sanyin ruwa (ana siyar dashi daban) | ||

| Girma | 1180x1070x1925mm | 1180x1070x1925mm | 3575*3500*4160mm |

| Nauyi | kusan 460kg | kusan 560kg | kusan 2150 kg |

| Ruwan Ruwa Mai Ruwa Mai Ruwa | hada | ||

Siffofin

HS-MI1 iyali ne na atomizers na ruwa wanda aka tsara don samar da foda na ƙarfe na sifar da ba ta dace ba, don amfani da ita a masana'antu, sinadarai, manna mai siyarwa, filtattun guduro, MIM da aikace-aikacen sintering.

Atomizer ya dogara ne akan tanderun shigar da bayanai, yana aiki a cikin rufaffiyar ɗaki ƙarƙashin yanayi mai kariya, inda aka zubar da narkakken ƙarfen kuma ya buge shi da jet na ruwa mai ƙarfi, yana samar da foda mai kyau da narke.

Induction dumama yana tabbatar da kyakkyawan daidaituwa na narkewar godiya ga aikin motsawar maganadisu yayin lokacin narkakken.

Naúrar mutu tana sanye take da ƙarin induction janareta, wanda ke ba da damar sake kunna zagayowar idan akwai katsewar sake zagayowar.

Bayan matakan narkewa da haɗin kai, ana zubar da ƙarfe a tsaye ta hanyar tsarin allura da aka sanya akan ƙananan tushe na crucible (bututun ƙarfe).

Matsaloli da yawa na ruwa mai matsa lamba suna nufin kuma suna mai da hankali kan katako na ƙarfe don tabbatar da ingantaccen ƙarfi mai sauri a cikin nau'in foda mai kyau.

Matsalolin tsari na lokaci-lokaci irin su zafin jiki, matsa lamba gas, ikon shigar da ruwa, abun ciki na oxygen ppm a cikin ɗakin da sauransu da yawa, ana nuna su a cikin nau'i na ƙididdiga da zane-zane akan tsarin kulawa don fahimtar fahimtar yanayin aiki.

Ana iya sarrafa tsarin da hannu ko a cikin cikakken yanayin atomatik, godiya ga shirye-shiryen duk saiti na sigogin tsari ta hanyar mai amfani da allon taɓawa.

Tsari Na Yin Foda Karfe Ta Ruwan Atomization Kayan Aikin Juya

Tsarin yin foda na ƙarfe ta hanyar ruwa atomization pulverizing kayan aiki yana da dogon tarihi. A zamanin d ¯ a, mutane suna zuba narkakkar ƙarfe a cikin ruwa don ya fashe cikin ɓangarorin ƙarfe masu kyau, waɗanda ake amfani da su azaman ɗanyen ƙarfe don yin ƙarfe; har ya zuwa yanzu, akwai mutanen da ke zuba dalma dalma kai tsaye a cikin ruwa don yin kwalwar dalma. . Yin amfani da hanyar atomization na ruwa don yin foda mara nauyi, ƙa'idar tsari iri ɗaya ce da ruwan da aka ambata a sama mai fashe ruwan ƙarfe, amma an inganta ingantaccen aikin ɗigon ruwa.

The ruwa atomization pulverizing kayan aiki sa m gami foda. Da farko, an narkar da gwal ɗin gwal a cikin tanderun. Ruwan zinare da aka narke dole ne a yi zafi da shi da kusan digiri 50, sannan a zuba a cikin tundish. Fara famfo mai matsa lamba na ruwa kafin a yi allurar ruwan gwal, kuma bari babban na'urar atomization na ruwa ta fara aikin. Ruwan zinare a cikin tundish yana wucewa ta cikin katako kuma ya shiga cikin atomizer ta bututun ruwa mai zube a kasan tundish. Atomizer shine mabuɗin kayan aiki don yin ƙaƙƙarfan foda na gwal ta hanyar hazo mai ƙarfi. Ingancin na'urar atomizer yana da alaƙa da murkushe ingancin ƙarfe foda. Karkashin aikin ruwa mai matsa lamba daga atomizer, ruwan gwal yana ci gaba da karyewa zuwa ɗigo masu kyau, waɗanda ke faɗowa cikin ruwa mai sanyaya a cikin na'urar, kuma ruwan yana daɗa ƙarfi cikin sauri ya zama foda. A cikin tsarin gargajiya na yin foda na ƙarfe ta hanyar atomization na ruwa mai ƙarfi, ana iya tattara foda na karfe gabaɗaya, amma akwai yanayin cewa ɗan ƙaramin foda na ƙarfe ya ɓace tare da ruwan atomizing. A cikin aiwatar da yin alloy foda ta hanyar atomization na ruwa mai ƙarfi, samfurin atomized yana mai da hankali a cikin na'urar atomization, bayan hazo, tacewa, (idan ya cancanta, ana iya bushe shi, yawanci kai tsaye aika zuwa tsari na gaba.), Don samun lafiya Alloy foda, babu asarar gami foda a cikin dukan tsari.

Cikakken saitin na'urar atomization na ruwa Kayan aiki don yin gami foda ya ƙunshi sassa masu zuwa:

Bangaren narkewa:Za a iya zaɓar tanderun ƙarfe na ƙarfe na tsaka-tsaki ko babban tanderun ƙarfe na ƙarfe. An ƙayyade ƙarfin wutar lantarki bisa ga girman aiki na foda na karfe, kuma za a iya zaɓar tanderun kilo 50 ko tanderun kilo 20.

Bangaren atomization:Kayan aiki a cikin wannan bangare ba kayan aiki ba ne, wanda ya kamata a tsara shi kuma a tsara shi bisa ga yanayin wurin mai sana'a. Akwai mafi yawan tundishes: lokacin da aka samar da tundish a cikin hunturu, yana buƙatar a rigaya; Atomizer: Atomizer zai fito daga babban matsi Ruwan famfo mai ƙarfi yana tasiri ruwan gwal daga tundish a ƙayyadaddun gudu da kusurwa, yana karya shi cikin ɗigon ƙarfe. Karkashin matsa lamba na famfo guda ɗaya, adadin foda mai kyau na ƙarfe bayan atomization yana da alaƙa da ingancin atomization na atomizer; Silinda atomization: shine wurin da ake karkatar da foda, a niƙa, sanyaya da tattara. Don hana ultra-fine alloy foda a cikin foda da aka samu daga rasawa da ruwa, ya kamata a bar shi na wani lokaci bayan atomization, sa'an nan kuma sanya shi a cikin akwatin tattara foda.

Bangaren sarrafawa:Akwatin tattara foda: ana amfani da shi don tattara foda mai atomized da raba da cire ruwa mai yawa; bushewa tanderu: bushe da rigar gami foda da ruwa; Injin nuni: sieve da gami foda, Za a iya sake narkar da foda mai ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwan da za a iya narkar da su a matsayin kayan dawowa.

Haɓaka Haɓaka Na Atomization Pulverizing Kayan Aiki Nan gaba

Har yanzu akwai nakasu da yawa a cikin fahimtar fasahar bugu na 3D a dukkan fannonin masana'antun kasar Sin. Yin la'akari da halin da ake ciki na ci gaba, ya zuwa yanzu 3D bugu bai samu balagagge masana'antu ba, daga kayan aiki zuwa samfurori zuwa ayyuka har yanzu a cikin mataki na "ci gaba". Duk da haka, daga gwamnati har zuwa kamfanoni a kasar Sin, ana ganin ci gaban fasahar buga fasahohin 3D gaba daya, kuma gwamnati da al'umma gaba daya sun mai da hankali kan tasirin da fasahar buga karfen atomization na 3D a nan gaba zai haifar da fasahohin samar da kayayyaki da tattalin arzikin kasata. da kuma masana'antu model.

Dangane da bayanan binciken, a halin yanzu, buƙatun ƙasata na fasahar bugu na 3D ba ta ta'allaka ne kan kayan aiki ba, amma tana nunawa a cikin nau'ikan bugu na 3D iri-iri da kuma buƙatar sabis na sarrafa hukuma. Abokan ciniki na masana'antu sune babban karfi wajen siyan kayan aikin bugawa na 3D a cikin ƙasata. Kayan aikin da suke saya ana amfani da su ne a fannin jiragen sama, sararin samaniya, kayayyakin lantarki, sufuri, ƙira, ƙirƙira al'adu da sauran masana'antu. A halin yanzu, ikon shigar da na'urorin buga na'urorin 3D a cikin kamfanonin kasar Sin ya kai kusan 500, kuma yawan karuwar da ake samu a shekara ya kai kusan kashi 60%. Duk da haka, girman kasuwar yanzu kusan yuan miliyan 100 ne kawai a kowace shekara. Bukatar R&D da samar da kayan bugu na 3D ya kai kusan yuan biliyan 1 a kowace shekara. Tare da haɓakawa da ci gaban fasahar kayan aiki, sikelin zai yi girma cikin sauri. A lokaci guda, 3D bugu da alaka da sarrafawa ayyuka ne Popular, da kuma da yawa jamiái 3D bugu Kamfanin kayan aiki ne sosai balagagge a cikin Laser sintering tsari da kayan aiki aikace-aikace, kuma zai iya samar da waje aiki ayyuka. Tun da farashin kayan aiki guda gabaɗaya ya haura yuan miliyan 5, karɓuwar kasuwa ba ta da yawa, amma sabis ɗin sarrafa hukumar ya shahara sosai.

Yawancin kayan da aka yi amfani da su a cikin na'urorin bugun ƙarfe na atomization na 3D na ƙasata ana samar da su kai tsaye daga masana'antun kera samfuri masu sauri, kuma ba a aiwatar da samar da kayan gabaɗaya na ɓangare na uku ba, wanda ke haifar da tsadar kayayyaki. A lokaci guda, babu wani bincike kan shirye-shiryen foda da aka keɓe don bugu na 3D a kasar Sin, kuma akwai ƙaƙƙarfan buƙatu akan rarraba girman ƙwayar cuta da abun ciki na oxygen. Wasu raka'a suna amfani da foda na yau da kullun maimakon, wanda ke da rashin amfani da yawa.

Haɓakawa da samar da ƙarin kayan aiki iri-iri shine mabuɗin ci gaban fasaha. Magance matsalolin aiki da tsadar kayayyaki zai fi inganta haɓaka fasahar yin samfuri cikin sauri a kasar Sin. A halin yanzu, galibin kayayyakin da ake amfani da su wajen buga fasahar 3D na kasata na bukatar a shigo da su daga kasashen waje, ko kuma masana’antun da ke kera kayan aikin sun zuba kudi da yawa don bunkasa su, wadanda suke da tsada, wanda hakan ya haifar da tsadar kayayyakin da ake samarwa, yayin da ake samun karuwar farashin kayayyaki. kayan gida da ake amfani da su a cikin wannan injin suna da ƙarancin ƙarfi da daidaito. . Ƙaddamar da kayan bugawa na 3D yana da mahimmanci.

Titanium da titanium gami foda ko nickel-tushen da kuma cobalt tushen superalloy powders tare da low oxygen abun ciki, lafiya barbashi size da high sphericity ake bukata. The foda barbashi size ne yafi -500 raga, da oxygen abun ciki ya zama ƙasa da 0.1%, da barbashi size ne uniform A halin yanzu, high-karshen gami foda da masana'antu kayan aiki har yanzu yafi dogara a kan shigo da. A kasashen waje, ana hada danyen kaya da kayan aiki da yawa ana sayar da su don samun riba mai yawa. Ɗaukar foda mai tushen nickel a matsayin misali, farashin albarkatun ƙasa ya kai yuan 200/kg, farashin kayayyakin gida gabaɗaya yuan 300-400 ne, kuma farashin foda da ake shigo da shi sau da yawa ya fi yuan 800/kg.

Misali, tasiri da daidaitawa na abun da ke cikin foda, haɗawa da kaddarorin jiki akan abubuwan da ke da alaƙa na 3D bugu na ƙarfe atomization foda milling kayan aiki. Saboda haka, a cikin ra'ayi na amfani da bukatun da low oxygen abun ciki da lafiya barbashi size foda, shi ne har yanzu wajibi ne don gudanar da wani bincike aikin kamar abun da ke ciki zane na titanium da titanium gami foda, gas atomization foda milling fasahar na lafiya barbashi size foda, da kuma. tasirin halayen foda akan aikin samfur. Saboda ƙayyadaddun fasahar niƙa a kasar Sin, yana da wuya a shirya foda mai kyau a halin yanzu, yawan foda yana da ƙasa, kuma abun ciki na oxygen da sauran ƙazanta yana da yawa. A yayin aiwatar da aikin, yanayin narkewar foda yana da haɗari ga rashin daidaituwa, yana haifar da babban abun ciki na haɗaɗɗun oxide da samfuran ƙima a cikin samfurin. Matsalolin da ke tattare da foda na gida suna cikin ingancin samfurin da kwanciyar hankali, ciki har da: ① kwanciyar hankali na abubuwan foda (yawan haɓakawa, daidaito na kayan aiki); ② foda jiki Kwanciyar aiki (rarrabuwar girman barbashi, foda ilimin halittar jiki, fluidity, sako-sako da rabo, da dai sauransu); ③ matsala na yawan amfanin ƙasa (ƙananan yawan amfanin ƙasa na foda a cikin kunkuntar girman girman sashi), da sauransu.

Nuni samfurin

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur